Triple Roller Guide (TRG) – Key Component for Piercing Mills

The Triple Roller Guide (TRG), a crucial component of piercing mills, plays a vital role in ensuring the precise and efficient operation of the tube piercing process. TRG is designed to support the proper alignment and guidance of billets as they pass through the piercing mill. This part helps maintain the quality of seamless steel pipe production by preventing misalignment, which can lead to defects in the final product. Given the importance of TRG in the production process, it is essential for maintaining the performance, efficiency, and longevity of the equipment.

Types of Triple Roller Guide:

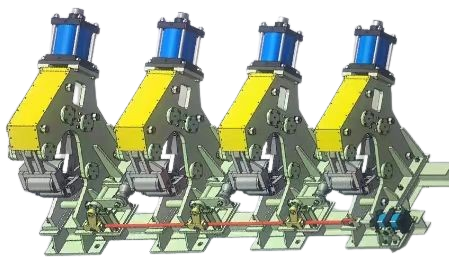

The Triple Roller Guide typically comes in two main types: Rack Type and Lever Type, each with its own set of advantages, depending on the specific needs and requirements of seemless tube production line.

-

Rack Type Triple Roller Guide:

The rack-type design is more commonly used in piercing mills that require high precision and consistency. This version is composed of a set of fixed racks, allowing the rollers to be aligned with the billets with high accuracy. The rack type is particularly useful in setups where the alignment of billets is crucial for producing pipes with minimal defects in terms of size, shape, and wall thickness. The structure of this guide allows for greater control over the billet movement, ensuring smooth passage through the piercing process. -

Lever Type Triple Roller Guide:

The lever type, on the other hand, utilizes a lever mechanism to adjust the position of the rollers dynamically. This provides more flexibility in guiding billets of varying sizes and shapes. Lever-type TRGs are often chosen for production lines that require high versatility and adaptability in handling different materials or pipe dimensions. The dynamic adjustment feature allows the guide to accommodate changes in production requirements, making it ideal for situations where multiple tube specifications are being processed.

Customization and Options:

The Triple Roller Guide is customizable based on the requirements of the piercing mill and the specific production line needs. TRG systems are designed to support varying capacities and configurations, including options for 4, 5, 6, or even 7 rollers. The number of rollers can be selected according to the production line design and the specific needs of the client. This modularity ensures that the Triple Roller Guide can be adapted for different billet sizes, material types, and production speeds, making it a versatile solution for various industries.

The Role of Triple Roller Guide in Piercing Mills:

In the piercing mill process, billets are heated to high temperatures before being pierced to form seamless pipes. The Triple Roller Guide ensures that the billet stays centered and properly aligned as it enters the piercing mill. This alignment is crucial because misalignment can lead to uneven deformation, leading to defects in the pipe’s final structure.

The TRG’s rollers work in tandem to provide continuous guidance to the billet during the piercing process. This guidance prevents any deviation from the desired path, ensuring that the billet’s centerline remains consistent with the transmission and control centerline throughout the process. It helps in reducing eccentricity and ensures the final product is consistent in terms of diameter, thickness, and overall geometry.

Additionally, the Triple Roller Guide helps in limiting the ellipticity of the billet, which is a critical factor in preventing defects like premature cavity formation. By controlling the billet’s position, the TRG contributes to the efficient elongation of the material, promoting smooth and consistent processing that results in high-quality, uniform seamless pipes.

Advantages of Triple Roller Guide:

-

Precise Billet Alignment:

The TRG system ensures that billets remain perfectly centered, reducing the risk of misalignment during the piercing process. This helps in maintaining the overall quality of the seamless pipes produced. -

Reduced Defects:

By preventing misalignment and controlling the billet’s movement, the Triple Roller Guide helps to minimize the risk of defects such as ovality, wall thickness variation, and surface imperfections. -

Enhanced Efficiency:

The precise control provided by the TRG enables smoother, faster operations. This leads to increased throughput and improved overall efficiency in the production process. -

Durability and Longevity:

Triple Roller Guides are designed to withstand the harsh conditions of the piercing mill, including high temperatures, friction, and constant wear. The robust construction and high-quality materials used ensure that the TRG provides long-term, reliable service, minimizing the need for frequent replacements. -

Customization and Flexibility:

With multiple roller configurations (4, 5, 6, and 7 rollers), the TRG can be customized to suit the specific needs of the production line. This flexibility ensures that the system can handle a wide range of pipe sizes and production speeds. -

Low Maintenance:

The design of the Triple Roller Guide ensures that it requires minimal maintenance, reducing downtime and maintenance costs. With regular checks and proper care, the TRG can operate efficiently for extended periods, offering a cost-effective solution for seamless pipe production.

Materials and Construction:

The construction of the Triple Roller Guide is done using high-quality, wear-resistant materials designed to withstand the harsh conditions of the piercing mill. The rollers are made from specially selected alloys that offer excellent wear resistance, while the guide itself is constructed to handle the extreme forces and temperatures present during the piercing process. This ensures the TRG’s durability and performance, even under heavy usage.

Applications of Triple Roller Guide:

Triple Roller Guides are commonly used in seamless steel pipe production and are essential components in piercing mills used for the production of high-quality tubes. These include applications in industries such as:

-

Oil and Gas: For the production of pipes used in drilling, transportation, and refining processes.

-

Construction: For manufacturing pipes used in infrastructure and structural applications.

-

Automotive: For producing precision tubes used in vehicles and other automotive parts.

-

Aerospace: For the production of high-performance tubes used in aerospace applications.

The Triple Roller Guide (TRG) is an indispensable component of the piercing mill process. It provides critical support for billet alignment, ensuring that the seamless steel pipe production process is efficient, precise, and free from defects. Whether you choose the rack type or the lever type, the TRG can be customized to suit the specific needs of your production line, offering improved productivity, lower costs, and higher-quality finished products.