Steel Rod Bar Reheating Furnace | Energy-Efficient Thermal Processing

High-Performance Steel Rod Reheating Solutions

KWM Machinery’s Steel Rod Bar Reheating Furnace ensures uniform heating for carbon steel, alloy rods, and wire rods with ±5°C temperature control, achieving 98% thermal efficiency compliant with ISO 13579 standards.

Designed for forging, rolling, and heat treatment processes, our systems reduce energy costs by 35% compared to conventional gas-fired furnaces.

Key Features

-

Advanced Heating Technology

-

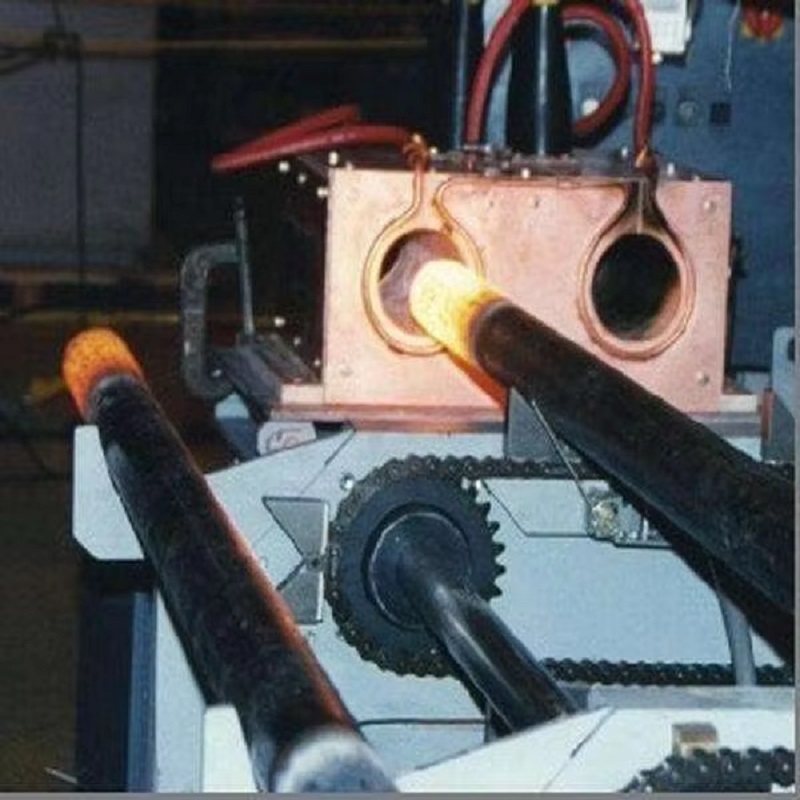

Induction Heating: 1-10kHz frequency range for precise depth control

-

Temperature Range: 200°C to 1,250°C (adjustable zones)

-

Capacity: 5-50 TPH continuous processing

-

-

Energy Optimization

-

Power Factor ≥0.95 (IGBT-based inverters)

-

Waste heat recovery for preheating feedstock

-

-

Smart Operation

-

AI-driven temperature profiling

-

Real-time rod surface oxidation monitoring

Steel Rod Bar heat treatment

-

Steel Rod Bar Heat Treatment Technical Advantages

-

Uniformity:

∙ Cross-section temperature gradient ≤8°C (ASTM E230)

∙ Automated skew correction for oval rods -

Material Flexibility:

∙ AISI 1045 | 4140 alloy steel | Stainless steel 316L -

Emission Control:

∙ NOx <30mg/Nm³ | CO emissions reduced by 50%

Steel Rod Bar Reheating Furnace Applications

| Industry | Typical Products | Standards |

|---|---|---|

| Automotive | Crankshaft forging blanks | SAE J404 |

| Construction | Rebar heat treatment | ASTM A615 |

| Fastener Manufacturing | High-strength bolts | ISO 898-1 |

| Energy | Drill rod preheating | API 7-1 |

Certifications & Safety

-

CE & ISO 14001 Certified

-

Safety Systems:

∙ Emergency water quenching (3s activation)

∙ Class F insulation (IEC 60085)

FAQ

Q: What’s the minimum rod diameter supported?

A: Φ8mm to Φ150mm with adaptive coil configurations.

Q: Can you handle irregular cross-sections?

A: Yes – square/flat bars up to 80mm thickness.

Q: How to prevent surface decarburization?

A: Nitrogen atmosphere option limits decarb to <0.05mm.

We also have Steel tube Rolling mill for whole production line –hot rolling mill and cold rolling mill.please contact for more details.