Steel Billet Rolling Mill | High-Efficiency Bloom & Billet Processing

Precision Billet Rolling Solutions

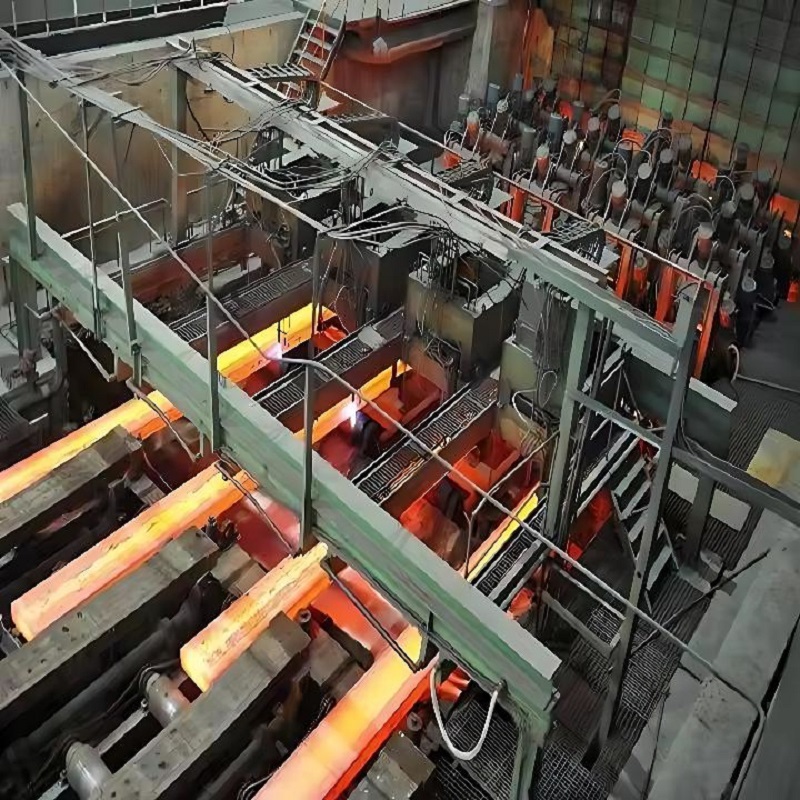

KWM Machinery’s Steel Billet Rolling Mill transforms 150x150mm to 300x300mm cast billets into blooms, bars, and sections with ±0.3mm dimensional accuracy, achieving 200-600 TPH output compliant with ASTM A615, EN 10025, and JIS G3101 standards. Our systems integrate continuous casting-rolling (CCR) technology, reducing energy consumption by 30% compared to traditional reversing mills.

Steel Billet Rolling Mill Key Features

-

High-Yield Rolling

-

Input Billet Size: 150x150mm – 300x300mm

-

Final Product:

∙ Bars: Φ20mm-Φ150mm

∙ Blooms: 200x200mm – 400x400mm -

Rolling Speed: 3-18m/s (variable via AI optimization)

-

-

Smart Process Control

-

Automatic gauge adjustment (AGC) with ±0.1mm precision

-

IoT-enabled roll wear monitoring (predictive maintenance)

-

-

Energy Efficiency

-

Regenerative DC drives recover 20% braking energy

-

Waste heat utilization for billet preheating (600-950°C)

-

Steel Billet Rolling Mill Technical Advantages

-

Surface Quality:

∙ Scale loss ≤0.8% with high-pressure water descaling (25MPa)

∙ Surface defects ≤0.1mm depth (EN 10221) -

Material Flexibility:

∙ Low-carbon steel (Q235) | Alloy steel (42CrMo4) | Stainless steel (304) -

Quality Assurance:

∙ Real-time temperature tracking (±5°C)

∙ In-line ultrasonic testing (UT) for internal flaws

Steel Billet Rolling Mill Applications

| Industry | Typical Products | Standards |

|---|---|---|

| Construction | Rebar feedstock (HRB500E) | GB/T 1499.2 |

| Automotive | Axle shafts (SAE 1045) | ISO 683-1 |

| Energy | Wind turbine shafts (34CrNiMo6) | EN 10083-3 |

| Heavy Machinery | Forging blanks (AISI 4140) | ASTM A29 |

Certifications & Safety

-

CE & ISO 50001 Certified

-

Performance Validation:

∙ 100-hour continuous rolling test (output tolerance ≤1.5%)

∙ Microstructure uniformity ≤5% variance (ISO 643)

CCM Billet Rolling Mill

FAQ

Q: What’s the minimum annual capacity?

A: 200,000 tons for basic models, expandable to 1M tons.

Q: Can you process alloy steel billets?

A: Yes – optimized for 42CrMo4, 20MnCr5, and other tool steels.

Q: How to reduce roll replacement downtime?

A: Quick-change cassettes (≤30min per stand) and Tungsten Carbide Rolls (HRC 65).

We also have whole production line –

Continuous Casting Rolling Line,

please contact for more details.