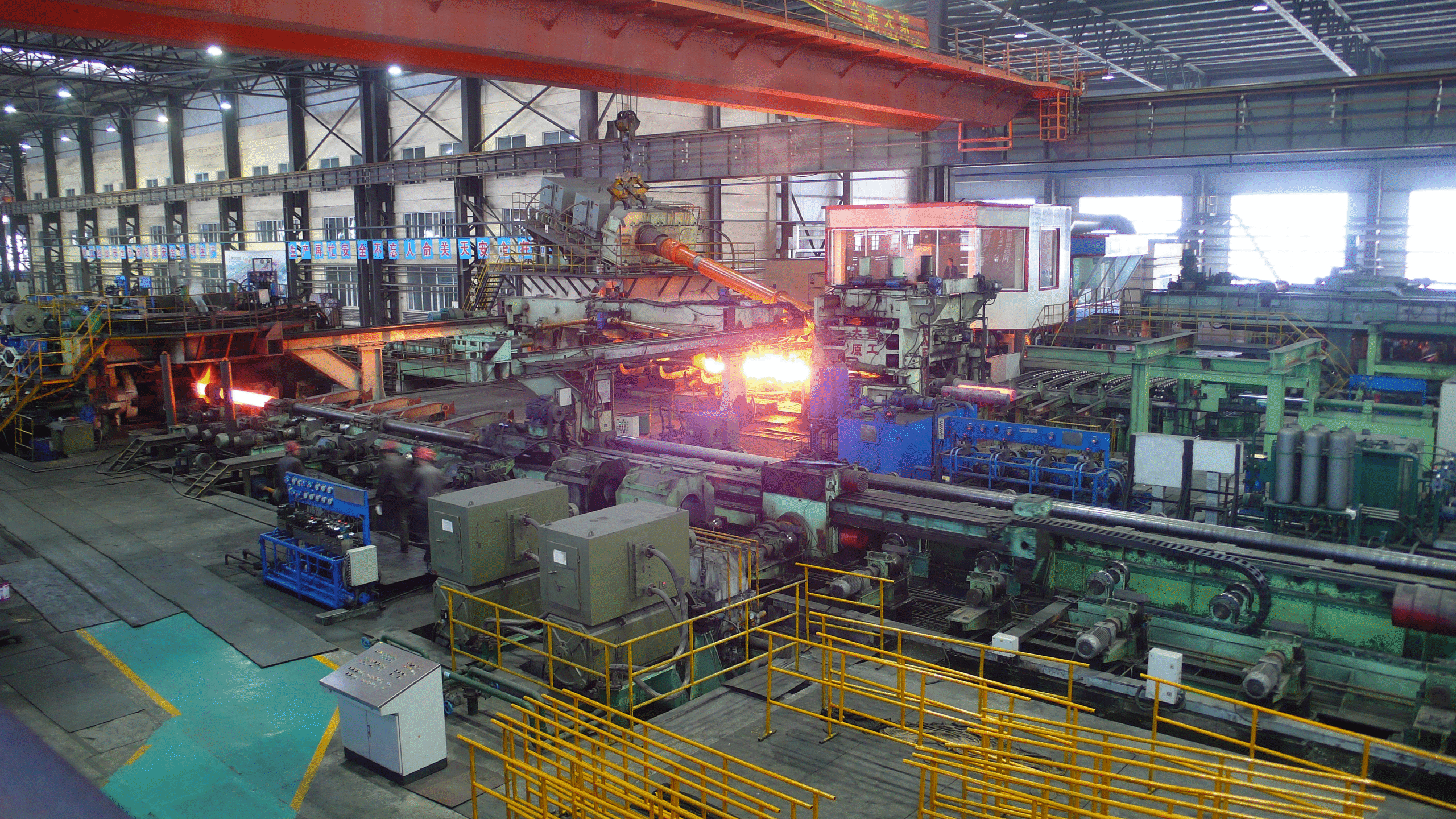

Seamless Tube Hot Rolling Line

The production process of seamless steel tube hot rolling line is to pierce the solid billet (or ingot) and roll it into steel tube with required shape, size and performance. The production of seamless tube ,after cutting ,round billets will be heated ,then pass piercing mill and sizing mill ,at last ,they are cooled on cooling bed .This technical process is suitable for small diameter and short length tube .Minimum diamter can be 23mm(OD) and length is about 6-7meters.

Main Parameter of Seamless Tube Hot Rolling Line

| Item | Description | RZJ80 | RZJ90 | RZJ114 | RZJ160 |

| 1 | Billet diameter (mm) | 60-110 | 65-130 | 80-180 | 140-230 |

| 2 | Billet length (m) | 2.0-3.0 | 1.6-2.4 | 1.5-2.6 | 1.7-3.0 |

| 3 | Shell diameter (mm) | 62-128 | 73-145 | 90-195 | 145-250 |

| 4 | Shell wall thickness (mm) | 5.0-26.0 | 5.0-22.0 | 5.0-25.0 | 10.0-40.0 |

| 5 | Shell length (m) | 3.5-7.5 | 3.5-7.5 | ≤7.0 | 5.0-9.0 |

| 6 | Hollow diameter (mm) | 55-122 | 68-138 | 87-175 | 140-230 |

| 7 | Hollow wall thickness (mm) | 4.5-25.0 | 4.5-20.0 | 4.5-23.0 | 8.0-38.0 |

| 8 | Hollow length (m) | 5.0-9.5 | 5.0-10.5 | ≤11.5 | 7.0-13.5 |

| 9 | Finished tube diameter (mm) | 51-114 | 57-133 | 76-168 | 133-219 |

| 10 | Finished tube wall thickness (mm) | 4.5-25.0 | 4.5-20.0 | 4.5-23.0 | 8.0-38.0 |

| 11 | Finished tube length (m) | ≤11.5 | ≤12.5 | ≤12.5 | ≤14.5 |

Main Process of Seamless Tube Hot Rolling Line

Billet Cutting – Inspection & Grinding – Billet Centering – Billet Heating –Pipe Piercing – Pipe Elongating – Pipe Sizing – Cooling – Straightening – Grinding & Testing – Cutting to Length – Inspection & Marking – Packing & Weighing — Storing

Main online machines include in Seamless Tube Hot Rolling Line:

Piercer machine, which is used to puncture the solide bar into hollow;

Skew rolling machine also called elongator, which is used to make the wall thickness thinner by rolling;

Sizing mill also called SRM mill, it is refining process and used to get finished size and precision;

Straightening machine is used to improve the straightness of MS steel pipe and tube;

Auxiliary parts include in cooling bed, roller way etc.

The finished products are widely used as structural tube, fluid tube, low and medium pressure boiler tube etc. directly. On the other hand, they can be used as raw materials of high end products.