Piercing Mandrel Plug

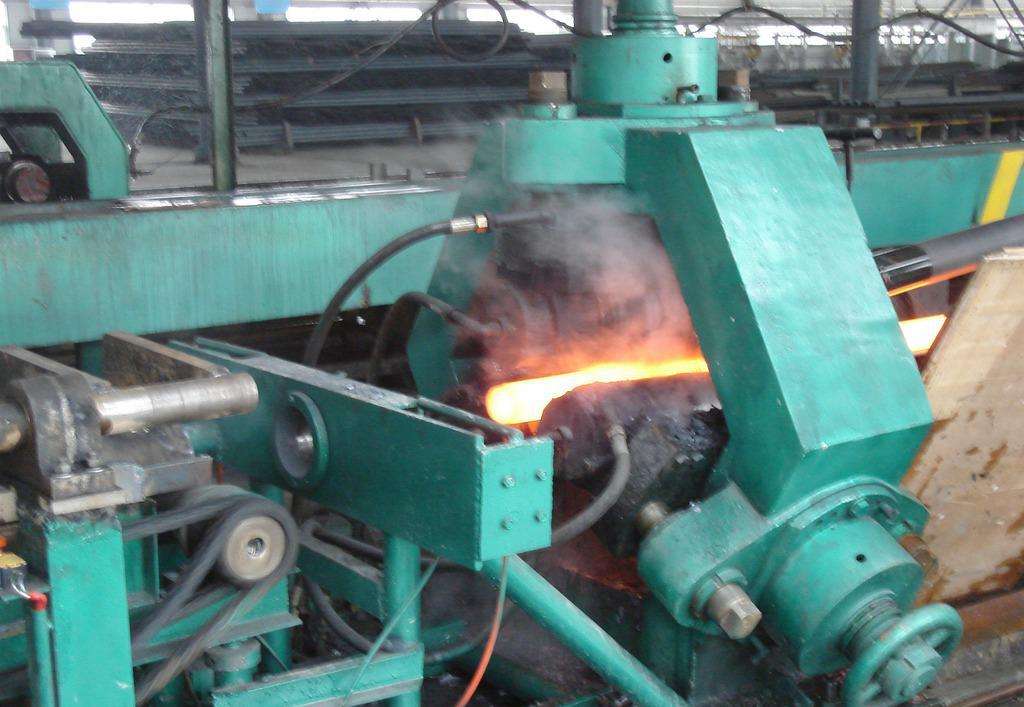

The Piercing Mandrel Plug is a vital tool in the production of seamless steel pipes. Due to its challenging working conditions, the piercing plug endures strong friction, extrusion, and repeated heat shock, which leads to wear and reduces its service life. To improve its performance, we have continuously refined the production technology, enhancing properties such as toughness, abrasion resistance, and heat resistance.

By adding alloy elements, the strength of the piercing mandrel plug has been significantly improved, providing excellent high-temperature resistance and extending its service life. This improvement results in a lifespan that is over three times longer than similar products, reducing overall production costs.

The piercing plug can be produced through casting or forging, depending on the material and intended use. Common materials include 35CrMo, H13, 20CrNi4, and pure molybdenum. Our advanced production processes ensure high-quality, durable piercing plugs.

According to the production mode, the plug is devided into casting plug or forging plug. We can make forged Hot Mill Piercer Tools Piercing Plug or casting Hot Mill Piercer Tools Piercing Plug according to the different material and use.

According to the material:

1)35CrMo

production process: round steel-cutting-heating-forging-finishing-testing-packaging

chemical composition:

| C | Si | Mn | S | P | Cr | Mo |

| 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 | 0.80-1.10 | 0.15-0.25 |

2)H13

medium frequency furnace melting – casting billet-heating-Forging-rough machining-heat treatment-finishing-inspection-packaging

hardness:38-42HRC

chemical composition:

| C | Si | Mn | Cr | Mo | V | P | S |

| 0.32-0.45 | 0.80-1.20 | 0.20-0.50 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 | ≤0.03 | ≤0.03 |

3)20CrNi4

20CrNi4 is mainly used for large piercer plug at present.

Surface treatment process: Nitriding oxidation, oxide layer thickness: 0.3-0.4mm

Hardness:260-320HB

chemical composition:

| C | Mn | Si | Cr | Mo | Ni | W | S | P |

| 0.17-0.23 | 0.45-0.65 | 0.45-0.65 | 1.5-1.8 | 0.35-0.45 | 3.2-3.8 | 0.2-0.5 | <0.025 | <0.025 |

4)Pure molybdenum plug

chemical composition:

| C | Mo | Ti | Zr | impurity |

| 0.1-0.5 | ≥95.5 | 1.0-2.0 | 0.1-0.5 | <0.03 |

We can supply piercing plug used on all kinds steel grade,such as carbon steel, alloy steel, stainless steel etc. Our piercing plug material are 35CrMo, H13,20CrNi4,Moly plug. Our design is good for piercing high qualified seamless steel pipes

Hot Tags: piercing mandrel plug, China, manufacturers, suppliers, factory, customized, piercing roll, piercer rolls, piercing guide shoes, seamless tube hot rolling line, piercer rolling ring, piercer plug.