Melting Furnace Machine | High-Efficiency Metal Smelting | KWM Machinery

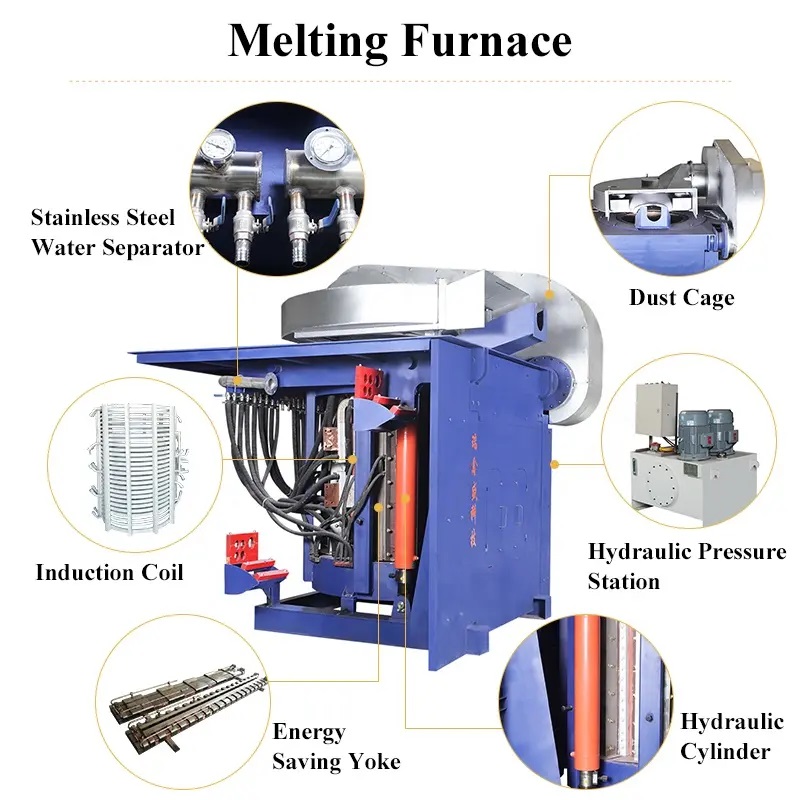

Precision Melting Furnace Machines for Industrial Foundries

KWM Machinery’s Melting Furnace Machine delivers energy-efficient metal smelting for steel, aluminum, copper alloys, and superalloys, achieving melt rates up to 12 tons/hour with ±5°C temperature control. Our systems comply with ISO 13579 thermal efficiency standards, reducing energy costs by 35% compared to conventional crucible furnaces.

Key Features

-

Advanced Heating Technology

-

Induction Melting: 1-20kHz frequency range for precise alloy control

-

Tilt Pouring System: 95% metal yield with slag separation

-

Capacity: 500kg to 50T batches

-

-

Energy Optimization

-

Power Factor ≥0.92 (IGBT inverter technology)

-

Waste heat recovery for preheating feedstock

-

-

Smart Operation

-

AI-driven melt cycle optimization

-

Real-time composition analysis via OES integration

-

Melting Furnace Machine Technical Advantages

-

Material Versatility:

∙ Carbon steel (AISI 1045) | Nickel alloys (Inconel 718) | Titanium (Grade 5) -

Emission Control:

∙ NOx <50mg/Nm³ | Particulate filtration efficiency 99.8% -

Safety Systems:

∙ Leak-proof crucible design | Emergency argon purge

| Rated Capacity (t) | Rated Power (KW) | Input Voltage (V) | Input Current (A) | DC Voltage (V) | DC Current (A) | IF Voltage (V) | IF Frequency (HZ) |

| 0.1 | 100 |

3 Phases 380V |

160 | 500 | 200 |

2200 |

100-1000 |

| 0.25 | 200 | 352 | 400 | ||||

| 0.5 | 400 | 650 | 800 | ||||

| 0.75 | 500 | 816 | 1000 | ||||

| 1 | 800 |

3 Phases 660V

|

730 |

890 |

900 |

3000 |

|

| 1.5 | 1200 | 1100 | 1350 | ||||

| 2 | 1500 |

6 Phases 750V |

612 |

1000 |

1500 |

3500 |

|

| 3 | 2000 | 816 | 2000 | ||||

| 5 | 3500 | 1428 | 3500 | ||||

| 8 | 5000 | 2040 | 5000 | ||||

| … | |||||||

Melting Furnace Machine Applications

-

Automotive: Engine block castings (SAE J431)

-

Aerospace: Turbine blade superalloy melting (AMS 5383)

-

Recycling: Scrap aluminum refining (EN 1706)

-

Jewelry: Precious metal smelting (99.99% purity)

Why Choose KWM Machinery?

-

CE & ISO 14001 Certified melting solutions

-

18+ years expertise in induction furnace engineering

-

Customized twin-chamber furnace configurations

-

Global spare parts network (48hr emergency dispatch)

FAQ

Q: What’s the minimum power requirement?

A: 500kW for 1T capacity, scalable to 10MW for 50T systems.

Q: Can you handle refractory metal melting?

A: Yes – our vacuum melting furnaces process tungsten/molybdenum up to 2,200°C.