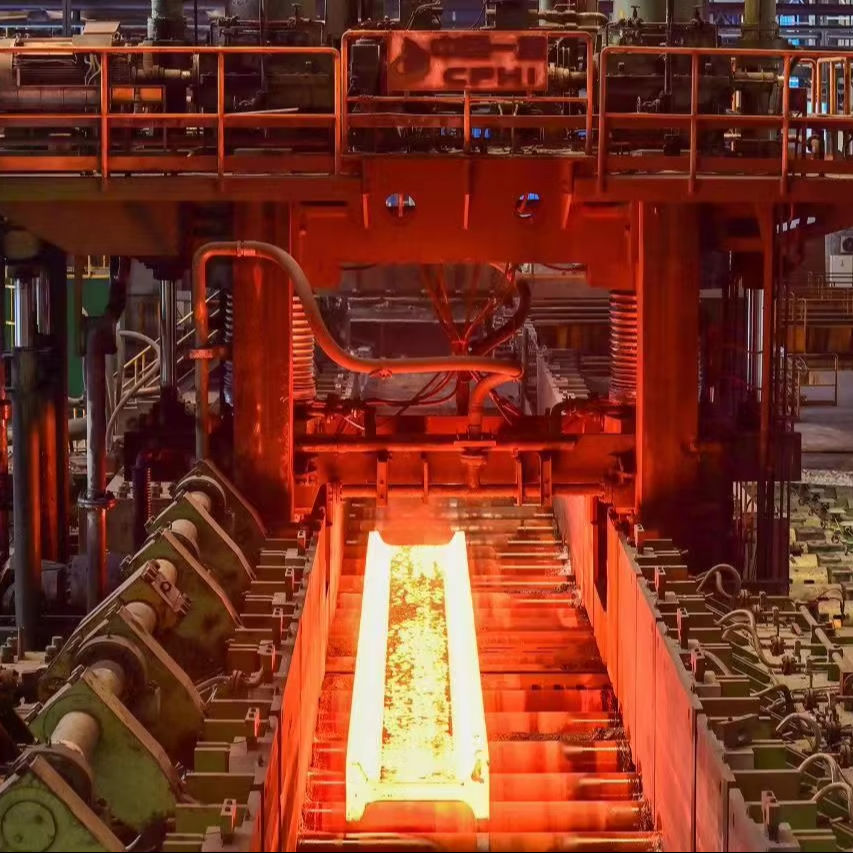

Hot-Rolled H-Beam Production Line

– Advanced Solutions for Section Steel Manufacturing

H-beams are essential for constructing beams, columns, bridges, oil drilling platforms, and more. With the demand for H-beams growing rapidly due to increased construction activities, especially in the industrial and civil sectors, having an efficient, high-capacity production line is critical. Our Hot-Rolled H-Beam Production Line turnkey services provide complete solutions for manufacturing hot-rolled H-beams, including the design, manufacturing, installation, and commissioning of production lines. These systems are customizable based on user requirements and can handle production capacities ranging from tens of thousands of tons to over a million tons annually.

Our production lines are equipped with the latest technologies and can accommodate varying rolling speeds (from 5 m/s to 95 m/s) and production needs (from small to large-scale operations). We provide comprehensive services, from conceptualization and engineering design to equipment manufacturing, commissioning, and operator training.

Key Features and Advantages of Hot-Rolled H-Beam Production Lines:

-

Customizable Production Capacity:

The production lines are designed with flexibility in mind, catering to a wide range of production capacities. Whether you need a small-scale production line with an output of 150,000 tons/year or a high-output system producing 700,000 tons/year, our Hot-Rolled H-Beam Production Lines can be tailored to meet specific requirements. This scalability allows businesses to expand production as demand increases, ensuring long-term growth potential. -

High-Precision Rolling:

The hot-rolling process is optimized for producing H-beams with consistent dimensions, excellent surface quality, and minimal deviations. Our production lines feature advanced universal rolling mills that ensure precise rolling of various products, including H-beams, T-beams, I-beams, angle steel, channel steel, and more. The integration of profile gauges and diameter measuring instruments ensures that the rolled products meet stringent dimensional and quality standards. -

Versatility in Material Processing:

Our production lines can handle a wide range of materials, including carbon structural steel, low-alloy high-strength structural steel, marine structural steel, and high-weathering steel. This versatility allows manufacturers to produce different grades of steel to meet diverse project requirements, ensuring high-quality products for various industries, such as construction, infrastructure, and marine applications. -

Optimized Rolling Speeds and Efficiency:

The rolling speeds of the H-beam production line can be adjusted to accommodate different material grades and thicknesses, ranging from 5 m/s to 95 m/s. This flexibility ensures that the production line can efficiently handle a wide variety of products, from small to large H-beams, and maintain high throughput while ensuring consistent product quality. -

Comprehensive Equipment Integration:

The Hot-Rolled H-Beam Production Line includes a wide range of equipment for a seamless manufacturing process, including:-

Heating Furnace: Prepares billets by heating them to the desired temperature before rolling.

-

High-Pressure Water Descaling: Removes surface impurities from the steel billets to ensure smooth rolling.

-

Universal Rolling Mills: Roll the billets into various section steel shapes, including H-beams, I-beams, and T-beams.

-

Multiple-Length Flying Shears: Automatically cut the rolled product into required lengths.

-

Cooling Bed: Cools the rolled H-beams to stabilize their properties.

-

Straightening Machine: Ensures the rolled products are straightened for high-quality output.

-

Bundling and Marking Equipment: Packages and labels the finished products for easy identification and transport.

-

-

Turnkey Solution and Engineering Expertise:

We offer turnkey services for the entire H-beam production process, from initial design to full installation and commissioning. Our team of engineers works closely with clients to design production lines that meet their specific requirements. We ensure that the entire system operates efficiently, with high uptime, minimal downtime, and optimized energy consumption. Moreover, we provide complete operator training to ensure that your team can operate the system to its full potential. -

High-Quality Finished Products:

The primary goal of our Hot-Rolled H-Beam Production Line is to deliver high-quality H-beams that meet all international standards for strength, durability, and dimensional accuracy. The production line produces H-beams with superior surface quality and consistent mechanical properties, making them ideal for use in a wide range of applications, including structural support for buildings, bridges, and oil rigs.

Production Process of Hot-Rolled H-Beam Production Line:

-

Billet Heating:

The first step in the hot-rolling process is heating the steel billets in a high-efficiency heating furnace to a temperature suitable for rolling. The billets are typically sized from 150mm x 10-12m to 200mm x 10-12m. -

Descaling:

High-pressure water is used to remove any scale or impurities from the surface of the billets, ensuring that the final product is free of defects that could affect surface quality. -

Rolling:

The billets are then fed into universal rolling mills, where they are shaped into the desired section, such as H-beams, T-beams, I-beams, or other structural shapes. The rolling process is optimized to ensure high precision and surface smoothness. -

Cutting:

After rolling, the beams are cut to length using multiple-length flying shears or a hot saw, depending on the production requirements. -

Cooling and Straightening:

The rolled products are cooled on a cooling bed and passed through a straightening machine to ensure they are perfectly aligned and free of any warping or bending. -

Bundling and Packaging:

Finally, the H-beams are bundled and marked with identification tags for easy handling and transportation. The finished products are ready for delivery or further processing.

Applications of Hot-Rolled H-Beams:

Hot-rolled H-beams are widely used in various industries, such as:

-

Construction: For beams and columns in residential, commercial, and industrial buildings.

-

Infrastructure: Used in bridges, highways, and other structural applications.

-

Oil and Gas: Essential for offshore oil rigs, drilling platforms, and pipeline supports.

-

Marine: Used in shipbuilding and other marine structures.

The Hot-Rolled H-Beam Production Line is an advanced and efficient solution for producing high-quality H-beams, which are essential in various industries such as construction, infrastructure, and energy. Our turnkey services ensure that clients receive a customized production line tailored to their specific needs, with the highest standards of quality, efficiency, and precision. With advanced features such as high-speed rolling, versatile material processing, and comprehensive equipment integration, our production lines provide reliable, cost-effective solutions for manufacturers in the steel industry.