Crocodile Scissors for Rolling Mill

Crocodile Scissors for Rolling Mill are heavy-duty cutting machines widely used in steel rolling mills for hot or cold cutting of metal bars, profiles, scrap, and intermediate products. Designed with a powerful jaw-type structure, crocodile scissors provide strong shearing force, high cutting efficiency, and stable operation, making them an essential auxiliary equipment in rolling mill production lines.

As a critical part of the rolling mill finishing and material preparation section, crocodile scissors are commonly applied for cutting billets, bars, rebars, section steel ends, and scrap generated during rolling and straightening processes. Their robust design ensures reliable performance even under harsh industrial conditions.

Application Fields

Crocodile Scissors for Rolling Mill are suitable for a wide range of applications, including:

- Bar rolling mills

- Section steel rolling mills

- Rebar production lines

- Seamless tube and pipe mills (auxiliary cutting)

- Steel scrap recycling and processing

- Rolling mill finishing and preparation areas

They are widely used to cut carbon steel, alloy steel, stainless steel, and other ferrous metal materials.

Key Features and Advantages

High Cutting Force and Efficiency

Equipped with a hydraulic or mechanical drive system, crocodile scissors deliver strong and stable shearing force, ensuring clean and fast cutting of metal materials with minimal deformation.

Heavy-Duty Structure for Rolling Mills

The machine frame and blades are manufactured from high-strength steel, offering excellent rigidity and wear resistance. This ensures long service life even under continuous rolling mill operations.

Flexible Cutting Range

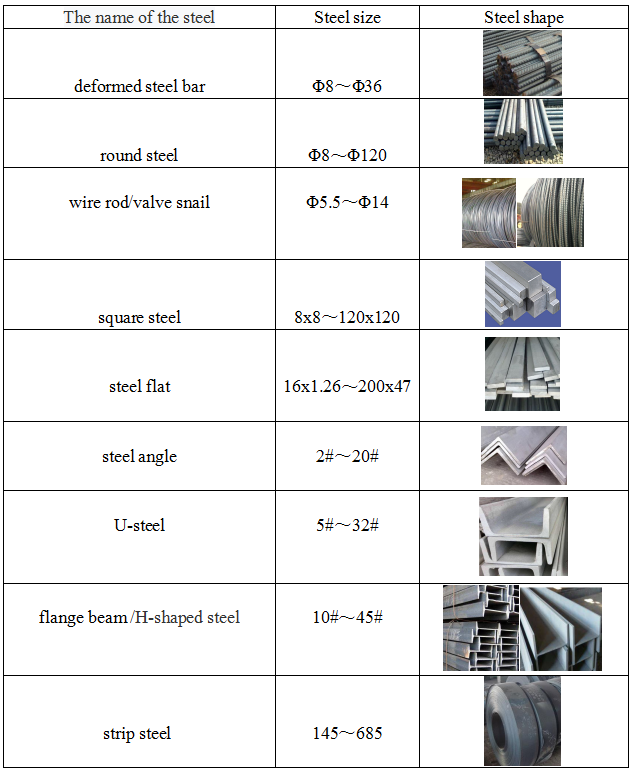

Crocodile scissors can handle various material sizes and shapes, including round bars, square bars, flat steel, angle steel, channel steel, and scrap materials generated during production.

Easy Operation and Low Maintenance

With a simple mechanical structure and reliable hydraulic system, the equipment is easy to operate, maintain, and service, reducing downtime and operating costs for steel plants.

Safe and Stable Performance

Designed with safety interlocks and stable clamping mechanisms, crocodile scissors ensure secure material positioning during cutting, improving operational safety.

Typical Working Principle

Crocodile scissors operate through a jaw-like cutting mechanism. Driven by a hydraulic cylinder or mechanical transmission system, the movable blade closes against the fixed blade, generating strong shearing force to cut metal materials efficiently. The cutting process is fast, smooth, and suitable for continuous rolling mill workflows.

Technical Configuration

- Drive type: Hydraulic or mechanical

- Blade material: High-alloy tool steel or hardened steel

- Cutting capacity: Customized according to material size and strength

- Control mode: Manual, semi-automatic, or automatic

- Installation: Floor-mounted or integrated with rolling mill line

Customized configurations are available to match different rolling mill layouts and production requirements.

Quality Assurance

To ensure reliable performance and long-term stability, each Crocodile Scissors for Rolling Mill undergoes strict quality inspection before delivery:

- Material inspection and hardness testing

- Dimensional and assembly accuracy checks

- Hydraulic system pressure testing

- Trial operation and cutting performance verification

Inspection reports such as size reports and quality certificates can be provided upon request.

Packing and Delivery

Packing:

The equipment is packed in standard export wooden cases or reinforced steel frames to ensure safety during long-distance transportation.

Delivery Time:

Typically 30–60 days depending on machine size, configuration, and order quantity.

Transportation:

Suitable for sea freight, land transport, or multimodal transportation according to customer requirements.

Why Choose Our Crocodile Scissors for Rolling Mill

- Proven experience in rolling mill equipment manufacturing

- Strong design and engineering capability

- Customized solutions for different rolling mill applications

- Stable performance and long service life

- Reliable after-sales service and technical support

Our crocodile scissors are trusted by steel plants and rolling mill operators worldwide for their durability, efficiency, and cost-effectiveness.