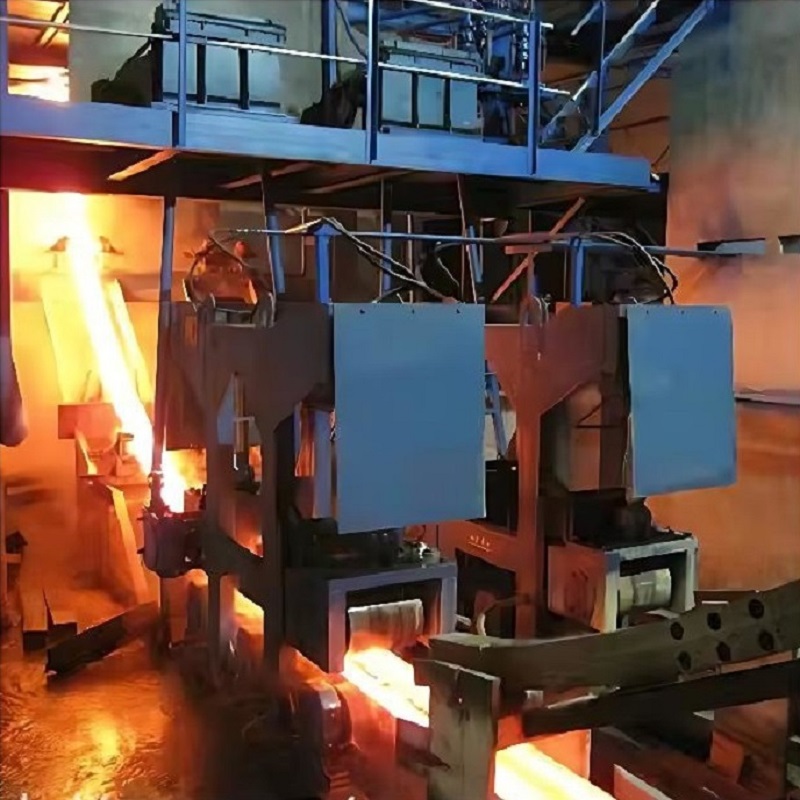

Continuous Casting Machine

High-Speed Steel Production | KWM Machinery

1. Continuous Casting Machines Introduction

KWM Machinery’s Continuous Casting Machine enables efficient production of billets, blooms, and slabs with 99.6% metal yield, revolutionizing molten steel processing for carbon steel, stainless steel, and specialty alloys. Our systems comply with ISO 14660 dimensional standards and deliver casting speeds up to 5.5m/min for high-volume foundries.

Continuous casting machine is the necessary equipment for Steel & Alloys production in metallurgical industry. It consists of ladle car, tundish, mould and vibration device, dummy bar, water cooler, tension leveler, cutting machine, cooling bed and electric control equipment.

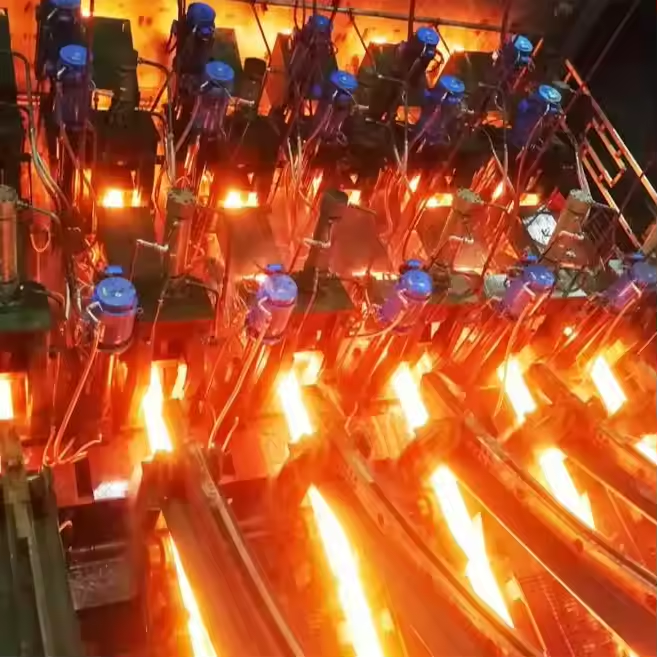

2. Continuous Casting Machines Steps:

Steel Scrap —- Melting Furnace —- Casting Machine —- Reheating Furnace —- Rolling Mill —- Severalfold Cut —– Cooling Bed —- Cut to length —- Collect Packaging

3.Continuous Casting Machines Key Features

-

High-Efficiency Casting

- Output Capacity: 500,000–2,000,000 tons/year

- Cast Section Sizes:

∙ Billets: 100×100mm – 200×200mm

∙ Blooms: 250×300mm – 400×500mm

∙ Slabs: 150×600mm – 250×1600mm

-

Intelligent Process Control

- Dynamic soft reduction (DSR) for internal quality

- AI-driven mold level stabilization (±0.5mm)

- Automated spray cooling with ±2°C precision

-

Energy Optimization

- 20% lower energy consumption vs. conventional casting

- Heat recovery systems for auxiliary power

4. Technical Advantages

- Zero Defect Surface: Electromagnetic stirring (EMS) for slag-free surfaces

- Material Flexibility:

∙ Low-carbon steel | Tool steel (AISI D2) | Duplex stainless steel - Quality Assurance:

∙ Online thermographic inspection | Segregation analysis (OES)

5.Applications

- Automotive: Gear steel billets (SAE 8620)

- Construction: Rebar-grade square billets (ASTM A615)

- Energy: Wind turbine shaft blooms (EN 10293)

- Aerospace: Titanium alloy slabs (AMS 4928)

6.Continuous Casting Machines Final Products

| 1. According to diameter | ||||

| Steel Wire | Ordinary Steel Bar | Thick Steel Bar | U-shaped steel | …… |

| Diameter 6 – 10 mm | Diameter 10 ~ 22 mm | Diameter greater than 22 mm | (20-350)*(20-100)*(0.5-12) | …… |

| 2. According to mechanical properties | ||||

| Grade I Reinforcement | Grade II Reinforcement | Grade III Reinforcement | Grade IV Reinforcement | |

| 235 / 420 grade | 335/455 grade | 400/540 grade | 500/630 grade | |

7.Why Choose KWM Machinery?

- CE & ISO 9001 Certified casting solutions

- 25+ years expertise in thin-slab continuous casting

- Customized curved/vertical casting machine designs

- 24/7 remote diagnostics via IoT platform

8.FAQ

Q: What’s the minimum production line length?

A: Compact layouts from 60m, adaptable to existing facilities.

Q: Can you upgrade older casting machines?

A: Yes – we retrofit automation packages and cooling zone optimizations.

Rmark: We also have Steel tube rolling mill.please check related products or homepage to know more.