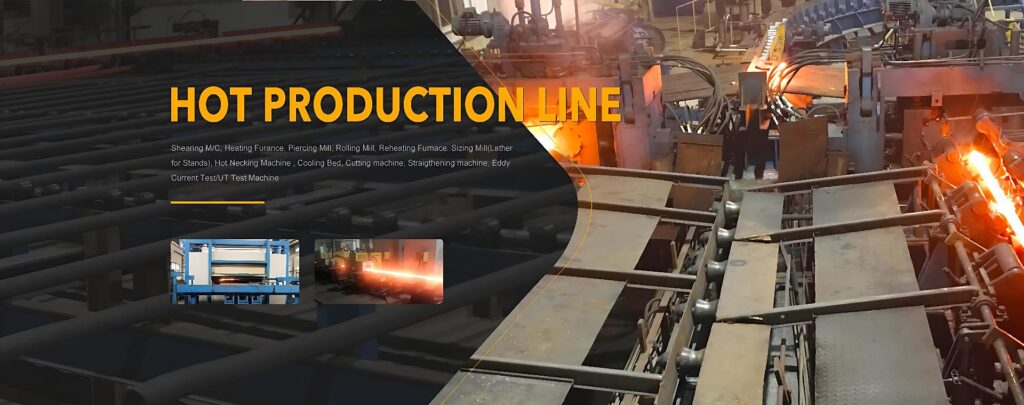

Precision Seamless Steel Tube Hot Rolling Mill Solutions

High-Efficiency Pipe Production | KWM Machinery

KWM Machinery delivers advanced Seamless Steel Tube Hot Rolling Mill engineered for superior dimensional accuracy and production efficiency. Our systems are designed to manufacture API 5L/ ASTM A106-grade seamless pipes with wall thickness consistency of ±0.5%, meeting rigorous industrial standards for oil & gas pipelines, boiler tubes, and structural components.

1.Key Production Machines:

Process flow:

Tube billet → Cutting → Heating → Piecing → Tube rolling → Sizing/Reducing → Straightening → Head and end cutting → Inspection → Packing → Storage

-

Piecing machine

Piecing machineTube billet piecing is the most important deformation process in hot rolled seamless tube production, its task is to roll solid tube billet into hollow capillary tube, according to the structure of piecing and deformation characteristics of perforation process, can be divided into: cross rolling perforation, push rolling perforation and pressure perforation, and cross rolling perforation is the most widely used.

Capillary rolling is the main deformation of hot-rolled seamless steel tube production process, its function is to make the tube thickness is close to or reached the wall thickness, finished product and the elimination of capillary in the perforation of longitudinal wall thickness is uneven, it also can improve the quality of tubes inside and outside of surface, control of waste pipe diameter and roundness, capillary rolled into close to finished size tubes. The pipe rolling mode is divided into automatic pipe rolling machine, continuous pipe rolling machine, (MPM two rolls continuous pipe rolling machine and PQF three rolls continuous pipe rolling machine), Assel roll rolling machine, Accu roll rolling machine and Pilger mill.

-

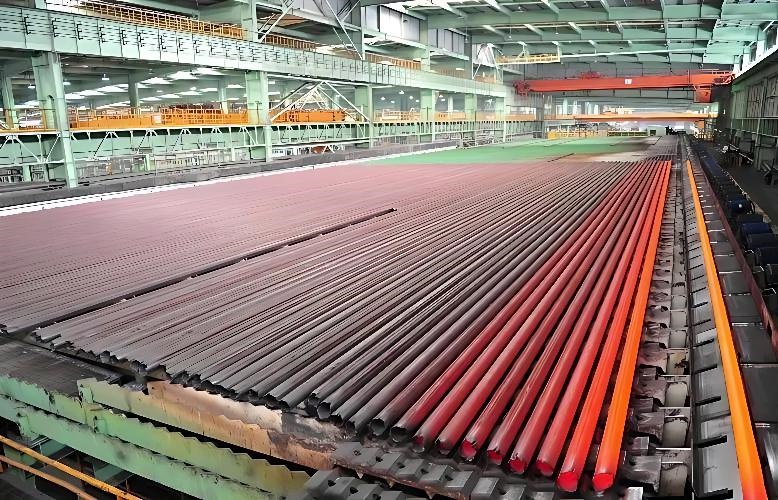

Sizing/Reducing machine

It is the last hot deformation process in the production of hot rolled seamless pipe. Its main function is to eliminate the discrepancy of outer diameter caused by the previous process of rolling. So as to improve the precision and roundness of outer diameter of hot rolled finished pipe. The process of tube sizing, reducing and tension reducing is the continuous rolling process without mandrel. At present, the domestic advanced sizing/reducing machine all use there roller 120° equal roller, using this form of sizing/reducing machine pipe surface quality is good, more specifications of finished pipe.

2.Seamless Steel Tube Hot Rolling Mill Key Features:

High-Yield Production

- Capacity: 50,000-200,000 tons/year

- Tube Diameter Range: Φ50mm to Φ340mm

- Temperature Control: ±10°C precision via AI-powered furnace systems

Advanced Rolling Technology

- Mandrel Mill Process (MPM) for uniform grain structure

- Automatic gauge adjustment (AGC) for ±0.15mm thickness tolerance

- Energy recovery systems reducing power consumption by 25%

Material Flexibility

- Compatible with carbon steel, alloy steel, and stainless steel (304/316L)

- Supports hot-rolled seamless pipes for high-pressure applications

3.Seamless Steel Tube Hot Rolling Mill Technical Advantages

- Seamless Pipe Rolling Efficiency: 30% faster cycle time vs. conventional mills

- Integrated Quality Assurance:

∙ Online ultrasonic testing (UT) for defect detection

∙ Real-time ovality monitoring (<1% deviation) - Smart Manufacturing: IoT-enabled predictive maintenance & OPC-UA connectivity

4.Applications

- Energy Sector: API 5CT casing pipes for oil drilling

- Power Plants: ASTM A335 P91/P92 high-temperature boiler tubes

- Infrastructure: EN 10210 structural hollow sections

Seamless Steel Tube machine

5.Why Choose KWM Machinery?

- ISO 9001 & CE Certified seamless tube equipment

- 20+ years of hot rolling mill manufacturing expertise

- Customized solutions for large-diameter seamless steel pipes

- Global service network with 48hr emergency response

6.FAQ

Q: What’s the minimum order quantity for your hot rolling mills?

A: 1 complete production line, tailored to your output requirements.

Q: Do you provide material testing support?

A: Yes – we offer metallurgical analysis and process simulation services.