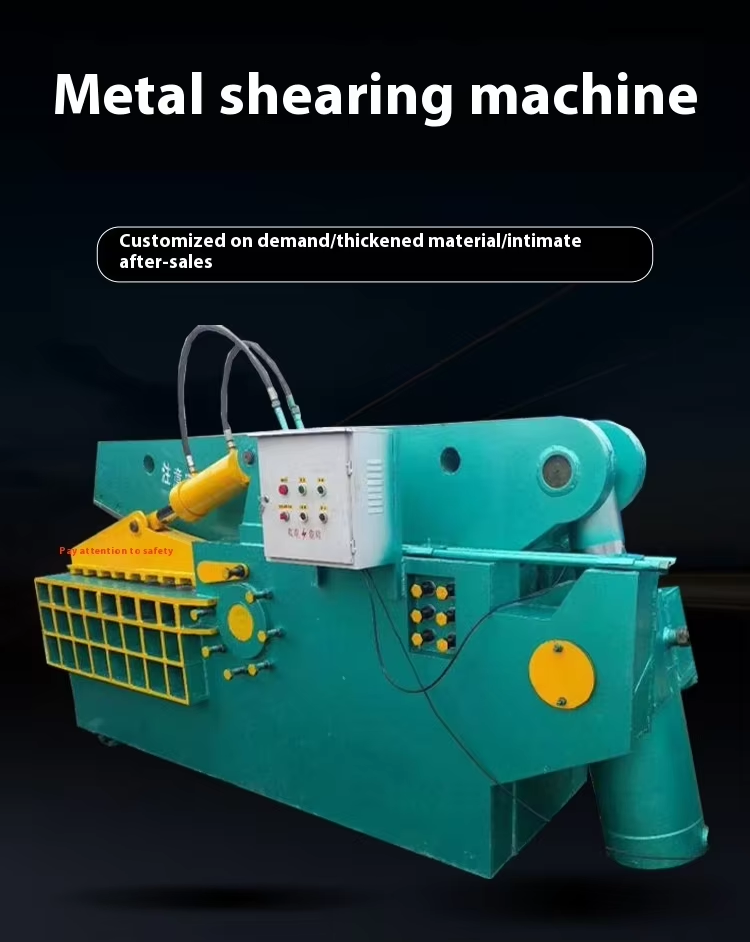

Metal Shear Cutting Machine

Heavy-Duty Metal Shear Cutting for Steel Processing Lines

The Metal Shear Cutting Machine is an essential cutting equipment widely used in steel rolling mills, metal fabrication plants, and industrial production lines. It is designed for accurate and efficient cutting of various metal materials such as steel plates, bars, pipes, sections, and strips. With a robust mechanical structure and reliable cutting performance, this machine ensures clean cutting edges, high productivity, and long service life.

Metal shear cutting machines are commonly integrated into hot rolling lines, cold rolling lines, section steel production lines, and finishing lines, playing a critical role in length cutting, head and tail trimming, and finished product preparation.

Applications

The Metal Shear Cutting Machine is suitable for:

-

Cutting steel plates and steel strips

-

Cutting bars, rods, and rebars

-

Cutting section steels such as angle steel, channel steel, H-beams, and I-beams

-

Cutting pipes and tubes

-

Head and tail cutting in rolling mill production lines

Typical industries include:

-

Metal processing and fabrication plants

-

Construction material production

-

Machinery manufacturing

-

Energy, shipbuilding, and infrastructure projects

Suitable Materials

-

Carbon steel

-

Alloy steel

-

Stainless steel

-

Structural steel

-

Non-ferrous metals such as aluminum and copper (optional configuration)

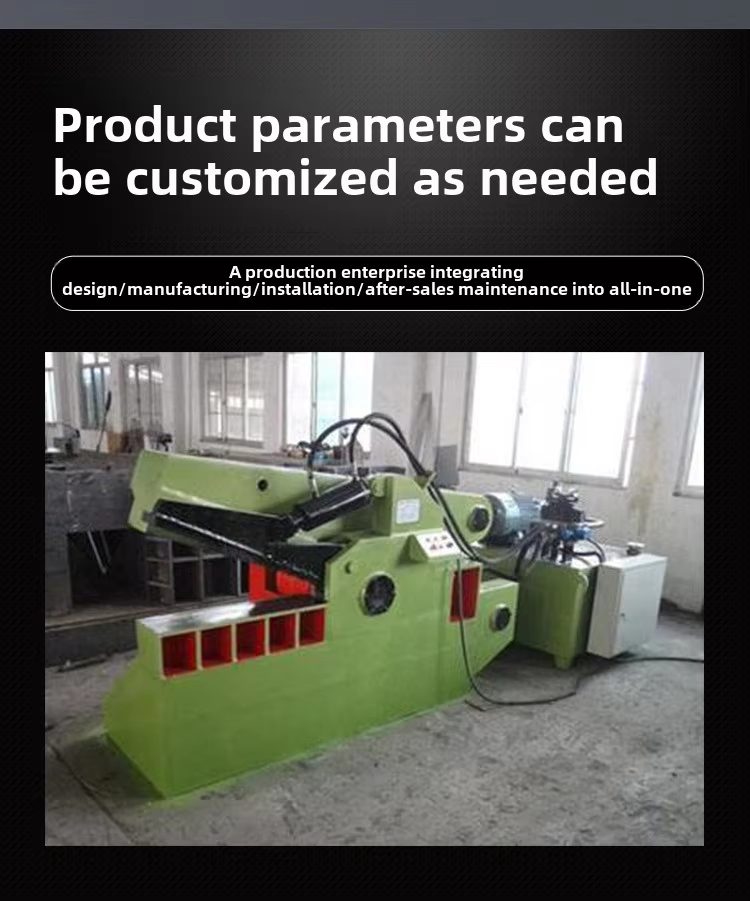

Machine Types

According to application and cutting method, metal shear cutting machines can be supplied as:

-

Mechanical metal shear cutting

-

Flying shear cutting machine

-

Crocodile shear cutting machine

Different configurations can be customized based on production line layout and cutting requirements.

Working Principle

The Metal Shear Cutting Machine operates by applying high mechanical or hydraulic force to drive the upper blade against the fixed lower blade. The metal material is positioned accurately, and the shear force causes clean separation along the cutting line.

In rolling mill applications, the machine can operate synchronously with material movement, enabling online cutting without stopping production, significantly improving line efficiency.

Key Advantages

-

High Cutting Accuracy

Ensures consistent length and smooth cutting edges. -

Strong Cutting Capacity

Designed for heavy-duty steel and high-strength materials. -

Stable and Reliable Operation

Rigid frame structure minimizes vibration and blade deflection. -

High Production Efficiency

Suitable for continuous and high-speed production lines. -

Flexible Configuration

Can be customized for hot cutting or cold cutting processes. -

Low Maintenance Cost

Durable blades and optimized mechanical design reduce downtime.

Main Components

-

Machine frame and base

-

Upper and lower shear blades

-

Hydraulic or mechanical drive system

-

Feeding and positioning device

-

Electrical control system (PLC optional)

-

Safety protection and guarding system

Production Process

-

Steel structure fabrication

-

Mechanical assembly

-

Blade installation and adjustment

-

Hydraulic and electrical system integration

-

Trial cutting and performance testing

-

Final inspection and export packing

Quality Assurance

-

Blade material and hardness inspection

-

Cutting accuracy and length tolerance testing

-

Load and continuous operation testing

-

MT and dimensional inspection reports available

Packing & Delivery

-

Export-standard wooden cases or steel frames

-

Rust-proof and moisture-proof protection

-

Suitable for long-distance sea transportation

-

Delivery time: 30–45 days depending on configuration

Why Choose Our Metal Shear Cutting Machine

-

Rich experience in rolling mill and steel processing equipment

-

Customized solutions based on production line layout

-

Stable cutting performance and long blade service life

-

Competitive investment cost and fast return on investment

-

Professional technical support and after-sales service

Our Metal Shear Cutting Machine helps steel producers improve cutting efficiency, reduce material waste, and ensure consistent product quality.