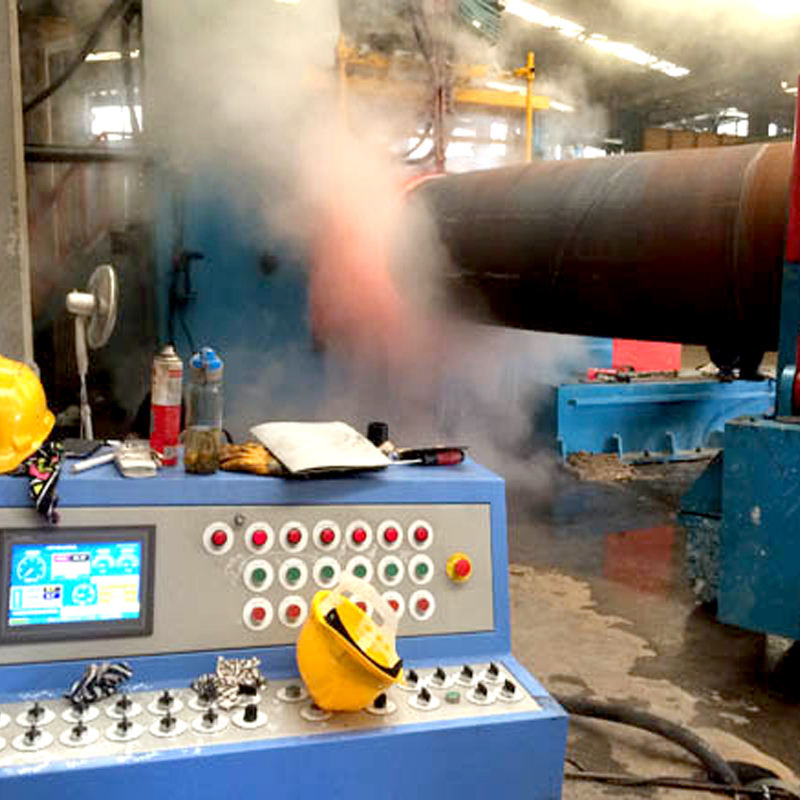

Hot Pipe Bending Machine

Industrial Hot Pipe Bending Machine for Seamless & Welded Pipes

The Hot Pipe Bending Machine is a specialized industrial machine designed for bending steel pipes at high temperatures, enabling precise shaping of seamless and welded pipes without compromising wall thickness or material integrity. By combining controlled heating and mechanical bending, this machine produces consistent, high-quality bends for pipelines used in oil & gas, petrochemical, power plants, and industrial piping systems.

Hot pipe bending machines are widely applied in pressure piping, boiler piping, pipeline construction, shipbuilding, offshore platforms, and industrial machinery, offering superior bending accuracy, repeatability, and structural reliability compared to cold bending methods.

Applications

This machine is ideal for producing:

-

45°, 60°, 90°, 180° bends for pipelines

-

Long-radius and short-radius bends

-

Bends in carbon steel, alloy steel, stainless steel, and special steel pipes

Common industries include:

-

Oil & gas transmission pipelines

-

Chemical and petrochemical plants

-

Power generation and thermal plants

-

Shipbuilding and offshore engineering

-

Industrial and structural piping systems

Suitable Materials

-

Carbon steel (A106, A53, API 5L)

-

Alloy steel (P11, P22, P91, etc.)

-

Stainless steel (304, 316, 321, 347, etc.)

-

Low-temperature steel, high-temperature steel, and special alloys

Working Principle

The hot pipe bending process involves heating the pipe to a plastic deformation temperature using an induction heater or furnace. The pipe is then bent around a precision forming die using hydraulic or servo-driven bending arms. This method ensures uniform wall thickness, minimal ovality, and smooth inner and outer surfaces.

Temperature, bending radius, and speed are precisely controlled to ensure repeatable, high-quality bends, reducing scrap rates and improving pipeline performance.

Key Advantages

-

Uniform Wall Thickness: Maintains pipe integrity during bending, avoiding thinning or cracks

-

High Accuracy & Repeatability: Precision bending dies and automated controls ensure consistent product quality

-

Wide Range of Pipe Sizes: Suitable for various diameters, wall thicknesses, and materials

-

Energy-Efficient Operation: Optimized heating and bending processes minimize energy consumption

-

High Automation: PLC or CNC control, automatic feeding, heating, bending, and cooling

-

Durable Design: Heavy-duty frame and hydraulic system ensure long-term reliability under continuous operation

Main Components

-

Pipe feeding and clamping system

-

Furnace or induction heating unit

-

Bending die and forming arm

-

Hydraulic or servo-driven power system

-

Cooling and calibration system

-

Electrical control panel with PLC or CNC

Production Process

-

Machine frame fabrication and assembly

-

Installation of hydraulic/servo system

-

Integration of heating system

-

Precision forming die setup

-

Trial bending and adjustment

-

Final inspection, testing, and packaging

Quality Assurance

-

Dimensional accuracy inspection

-

Wall thickness uniformity measurement

-

Surface quality evaluation

-

Load and operational testing

Reports for material certification, performance, and inspection can be supplied.

Packing & Delivery

-

Standard export wooden cases or steel frames

-

Moisture-proof and rust-preventive packing

-

Suitable for sea, land, or multimodal transportation

-

Delivery time: 30–60 days depending on configuration

Why Choose Our Hot Pipe Bending Machine

-

Extensive experience in pipeline and rolling mill equipment

-

Customizable solutions for pipe diameter, material, and bending radius

-

Stable operation, high repeatability, and long service life

-

Low maintenance cost with reliable after-sales support

-

Helps steel producers and contractors reduce scrap, increase efficiency, and meet international standards