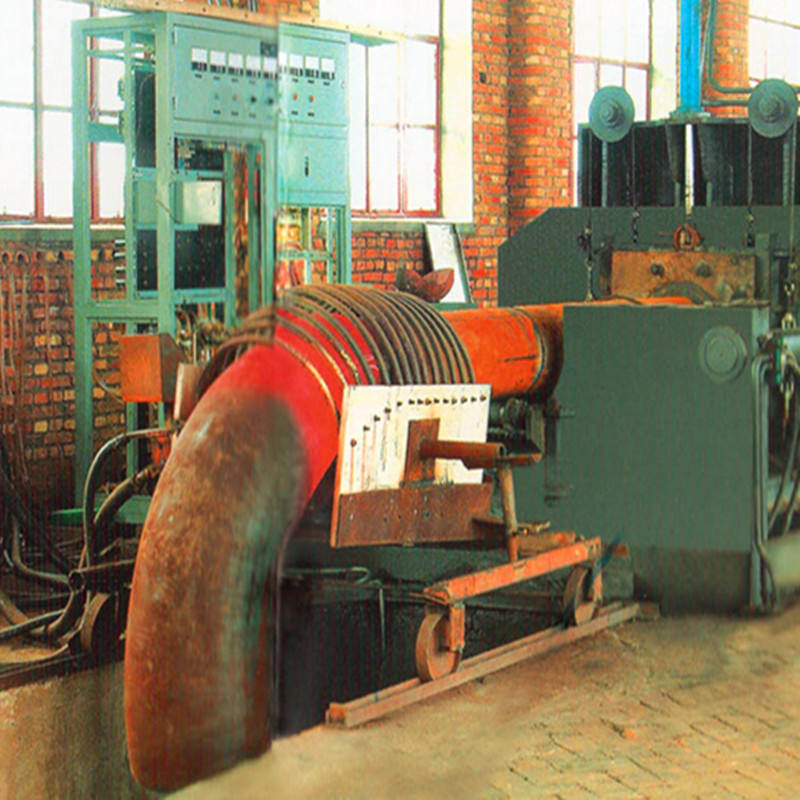

Hot Elbow Machine

Hot Forming Elbow Machine for Seamless & Welded Pipe Fittings

The Hot Elbow Machine is a specialized forming equipment used for manufacturing hot-formed pipe elbows from carbon steel, alloy steel, and stainless steel pipes. By heating the pipe to a high temperature and applying controlled mechanical forming, the machine produces elbows with uniform wall thickness, smooth inner surface, and high dimensional accuracy.

Hot elbow machines are widely used in oil & gas pipelines, power plants, petrochemical engineering, pressure piping systems, and industrial pipe fitting manufacturing plants. Compared with cold forming methods, hot forming ensures better material flow, higher strength retention, and superior product consistency.

Main Applications

The Hot Elbow Machine is suitable for producing:

-

Long radius and short radius elbows

-

45°, 60°, 90°, 180° elbows

-

Seamless steel pipe elbows

-

Welded steel pipe elbows

Typical application industries include:

-

Oil & gas transmission pipelines

-

Petrochemical and chemical plants

-

Thermal and nuclear power projects

-

Shipbuilding and offshore engineering

-

Industrial piping and pressure vessel systems

Suitable Materials

-

Carbon steel (ASTM A106, A53, API 5L, etc.)

-

Alloy steel (P11, P22, P91, etc.)

-

Stainless steel (304, 316, 321, 347, etc.)

-

Low-temperature and high-temperature steels

Working Principle

The Hot Elbow Machine works by heating the steel pipe to a plastic deformation temperature using an induction heating system or heating furnace. The heated pipe is then pushed or rotated around a forming die, allowing the material to flow evenly and form the required elbow radius and angle.

Through precise control of temperature, forming speed, and axial force, the machine ensures minimal wall thinning, uniform thickness distribution, and excellent surface quality.

Key Advantages

-

Uniform Wall Thickness

Optimized forming process reduces thinning and ovality during elbow forming. -

High Production Efficiency

Continuous hot forming allows stable, repeatable production. -

Wide Size Range

Suitable for various pipe diameters and wall thicknesses. -

Excellent Mechanical Properties

Hot forming maintains material strength and improves internal structure. -

High Automation Level

Optional PLC control, automatic feeding, and forming programs.

Main Components

-

Pipe feeding and clamping system

-

Induction heating or furnace heating system

-

Forming arm and die system

-

Hydraulic or mechanical drive unit

-

Cooling and calibration system

-

Electrical control and automation system

Each component is designed for heavy-duty industrial operation and long service life.

Technical Features

-

Accurate temperature control system

-

Heavy-duty forming structure

-

Replaceable forming dies for different sizes

-

Stable hydraulic or servo-driven operation

-

Optional online thickness and dimension control

Production Process

-

Machine structure fabrication

-

Mechanical assembly

-

Electrical and control system integration

-

Trial forming and accuracy testing

-

Final inspection and packing

Quality Assurance

-

Dimensional inspection of formed elbows

-

Wall thickness uniformity check

-

Surface quality inspection

-

Machine performance and load testing

Packing & Delivery

-

Export-standard wooden cases or steel frames

-

Electrical components moisture-protected

-

Suitable for long-distance sea transportation

-

Delivery time: 30–60 days, depending on configuration

Why Choose Our Hot Elbow Machine

-

Extensive experience in pipe forming equipment

-

Customized solutions based on pipe size and material

-

Stable forming quality and high reliability

-

Competitive investment cost and low maintenance

-

Professional after-sales service and technical support

Our Hot Elbow Machine helps customers produce high-quality elbows efficiently, reduce scrap rate, and meet international piping standards.