Seamless Tube Roll

High-Performance Rolls for Seamless Tube Rolling Mills

Seamless Tube Roll is a core rolling component used throughout seamless tube and pipe production lines. The performance of seamless tube rolls directly affects tube dimensional accuracy, wall thickness uniformity, surface quality, rolling stability, and overall production efficiency. During hot rolling and sizing processes, rolls operate under extremely harsh conditions, including high temperature, heavy rolling force, impact load, and continuous friction, making roll quality a critical factor for stable mill operation.

Our Seamless Tube Rolls are specially designed for seamless tube rolling mills such as piercing mills, elongating mills, mandrel mills, plug mills, stretch reducing mills, sizing mills, and straightening mills. With optimized material composition, advanced heat treatment, and precision machining, our rolls provide excellent wear resistance, thermal fatigue resistance, and long service life, helping tube producers achieve consistent product quality and lower production costs.

Applications

Our Seamless Tube Rolls are widely used in various stages of seamless tube production, including:

- Piercing mill rolls

- Mandrel mill rolls

- Plug mill rolls

- Elongating mill rolls

- Stretch reducing mill rolls

- Sizing mill rolls

- Straightening mill rolls

They are suitable for producing carbon steel tubes, alloy steel tubes, stainless steel tubes, boiler tubes, line pipes, structural tubes, and precision seamless pipes.

Key Advantages for Seamless Tube Producers

1. Excellent Wear Resistance and Long Service Life

Using high-quality alloy steel, high-chromium materials, and optimized microstructure design, our seamless tube rolls demonstrate outstanding resistance to wear, spalling, and thermal cracking, significantly extending roll campaign life.

2. Stable Rolling Performance

The rolls maintain stable hardness and mechanical strength under high-temperature rolling conditions, reducing vibration and ensuring smooth metal flow during tube deformation.

3. High Dimensional Accuracy

Precision roll profiles and strict machining tolerances help achieve uniform wall thickness, accurate outer diameter, and reduced ovality of seamless tubes.

4. Improved Surface Quality

Optimized surface finish and profile design minimize surface defects such as scratches, folds, chatter marks, and roll impressions on finished tubes.

5. Customized Roll Solutions

Roll materials, dimensions, groove design, and hardness distribution can be customized based on mill type, tube size range, steel grade, and production capacity.

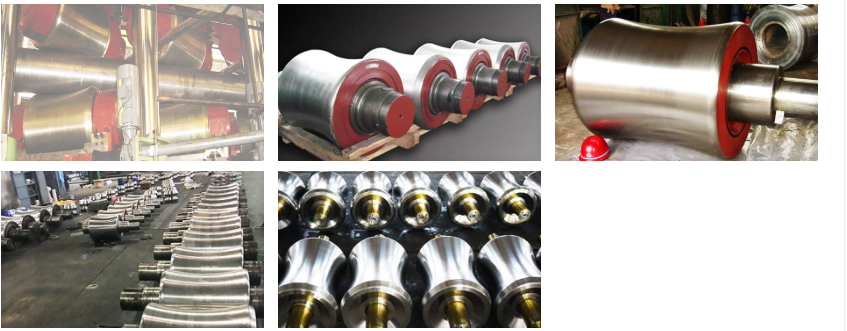

Roll Types Available

- Piercing rolls

- Mandrel mill rolls

- Plug mill rolls

- Stretch reducing mill rolls

- Sizing mill rolls

- Straightening rolls

Material Options

To meet different rolling conditions and tube grades, we offer multiple material solutions:

- Forged alloy steel rolls

- High-chromium cast iron rolls

- Adamite rolls

- High-speed steel (HSS) rolls

- Composite rolls (optional)

Material selection is optimized according to rolling temperature, deformation degree, rolling speed, and tube material.

Manufacturing Process

Each Seamless Tube Roll is manufactured under strict quality control procedures:

- Forging or centrifugal casting

- Rough machining

- Heat treatment (quenching and tempering or special treatment)

- Precision machining and roll profile grinding

- Non-destructive testing and final inspection

- Anti-corrosion protection and export packaging

Quality Assurance

To ensure reliable performance and consistency, all rolls undergo comprehensive inspection, including:

- Ultrasonic Testing (UT)

- Magnetic Particle Testing (MT)

- Hardness and hardness depth inspection

- Dimensional and profile inspection

- Surface quality inspection

Inspection reports and size certificates are provided with each delivery.

Why Choose Our Seamless Tube Rolls

- Extensive experience supplying seamless tube rolling mills worldwide

- Stable quality suitable for continuous industrial production

- Strong customization and engineering support capability

- Competitive cost with long service life

- Reliable delivery and professional after-sales service

Our Seamless Tube Rolls help tube producers improve rolling stability, enhance tube quality, and reduce overall operating costs.

Typical Supply Scope

- Rolls for complete seamless tube production lines

- Replacement rolls for existing mills

- Customized seamless tube rolls according to customer drawings or technical requirements

Contact Us

For technical consultation, roll selection, or customized seamless tube roll solutions, please contact us. Our technical team will provide professional support for your tube rolling mill.