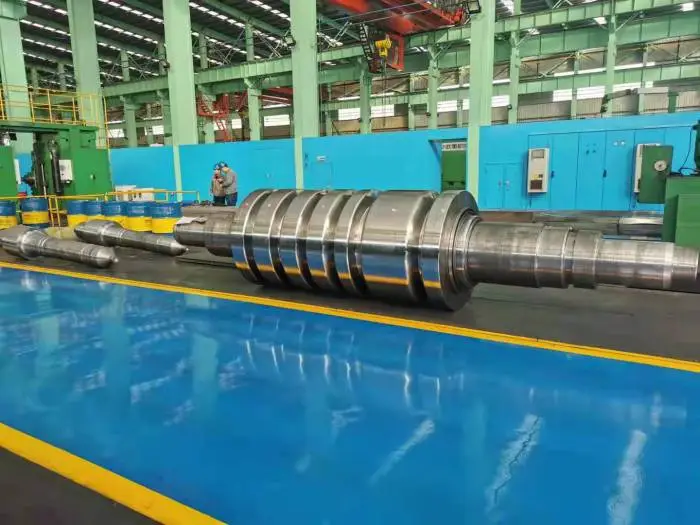

Section Steel Rolling Mill Rolls

High-Performance Rolls for Section Steel Rolling Mills

Section Steel Rolling Mill Rolls are key working components used in section steel rolling mills for producing various structural steel profiles. The performance of section mill rolls directly determines rolling stability, dimensional accuracy, surface quality, and production efficiency of section steel products. Under hot rolling conditions, these rolls are exposed to high temperature, heavy rolling force, impact load, and repeated thermal stress, making roll quality a decisive factor in mill operation.

Our Section Steel Rolling Mill Rolls are specially designed for angle steel, channel steel, I-beams, H-beams, flat steel, rails, and other section steel products. Through optimized material selection, advanced heat treatment, and precision machining, our rolls deliver excellent wear resistance, thermal fatigue resistance, and stable profile accuracy, ensuring consistent product quality and long roll service life.

Applications

Our Section Steel Rolling Mill Rolls are widely used in:

- Angle steel rolling mills

- Channel steel rolling mills

- I-beam and H-beam rolling mills

- Rail and special section rolling mills

- Roughing, intermediate, and finishing stands of section mills

They are suitable for rolling carbon steel, low-alloy steel, high-strength structural steel, and other special steel grades used in construction, infrastructure, bridges, machinery manufacturing, and energy industries.

Key Advantages for Section Steel Producers

1. High Wear and Impact Resistance

Using high-quality alloy materials and optimized microstructure design, our section steel rolling mill rolls offer excellent resistance to wear and impact load, significantly extending roll campaign life even under heavy-duty rolling conditions.

2. Excellent Thermal Fatigue Resistance

The rolls are designed to withstand frequent thermal cycling and water cooling during hot rolling, effectively reducing thermal cracking and surface spalling.

3. Accurate Profile and Dimensional Control

Precision roll pass design and high machining accuracy ensure stable section dimensions, sharp corners, and consistent geometry, helping customers meet strict dimensional tolerances.

4. Stable Rolling Performance

Our rolls maintain stable hardness and strength at elevated temperatures, reducing vibration, improving rolling stability, and supporting higher rolling speeds.

5. Customized Roll Solutions

Roll materials, groove design, hardness distribution, and dimensions can be customized based on section type, rolling stand position, billet size, and production capacity.

Roll Types Available

- Roughing mill rolls for section steel

- Intermediate mill rolls

- Finishing mill rolls

- Universal mill rolls for H-beam and I-beam

- Special rolls for rails and complex sections

Material Options

To meet different rolling requirements, we provide multiple material choices:

- Forged alloy steel rolls

- Adamite rolls

- High-chromium cast iron rolls

- High-speed steel (HSS) rolls

- Composite rolls (optional)

Material selection is optimized according to rolling temperature, rolling force, reduction ratio, and section complexity.

Manufacturing Process

Each Section Steel Rolling Mill Roll is produced under strict quality control:

- Forging or centrifugal casting

- Rough machining

- Heat treatment (quenching and tempering or special treatment)

- Precision machining and groove processing

- Non-destructive testing and final inspection

- Anti-corrosion protection and export packaging

Quality Assurance

To guarantee reliable performance, all rolls are inspected according to international standards:

- Ultrasonic Testing (UT)

- Magnetic Particle Testing (MT)

- Hardness and hardness depth inspection

- Dimensional and groove profile inspection

- Surface quality inspection

Inspection reports and size certificates are supplied with each delivery.

Why Choose Our Section Steel Rolling Mill Rolls

- Extensive experience supplying section steel rolling mills worldwide

- Stable and reliable quality for continuous industrial production

- Strong capability in groove design and customization

- Competitive cost with long service life

- Professional technical support and after-sales service

Our Section Steel Rolling Mill Rolls help producers improve rolling stability, enhance section accuracy, and reduce overall production costs.

Typical Supply Scope

- Rolls for angle steel, channel steel, and flat steel rolling

- Universal mill rolls for H-beam and I-beam production

- Customized rolls according to customer drawings or rolling conditions

Contact Us

For technical consultation, roll selection, or customized section steel rolling solutions, please contact us. Our engineers will provide professional support tailored to your rolling mill requirements.