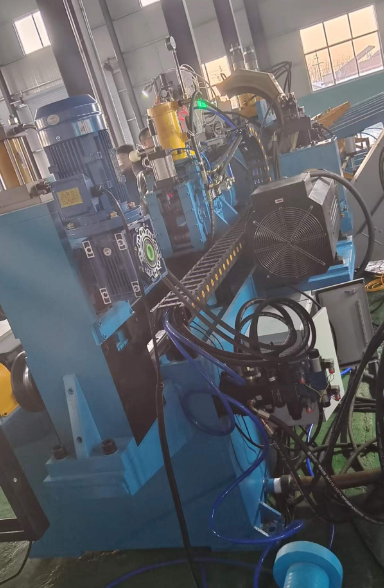

Seamless Tube Peeling Machine

– Precision Surface Treatment for Metal Materials

The Seamless Tube Peeling Machine is a specialized lathe used for the efficient rough and finishing processing of cylindrical materials such as bars, shafts, and tubes. The machine is designed to remove surface defects, such as decarburization layers, cracks, or other irregularities that might affect the quality of the final product. By removing these imperfections, the Seamless Tube Peeling Machine ensures that the material meets the required surface quality and dimensional accuracy, making it ideal for a wide range of applications in industries such as steel production, aerospace, automotive, and more.

This versatile machine is capable of processing a variety of metal materials, including ferrous metals such as steel, stainless steel, and tool steel, as well as non-ferrous metals like aluminum, copper, titanium, and their alloys. The Peeling Machine plays a crucial role in improving the surface finish and extending the service life of the products it processes. Whether you’re working with structural steel, alloy steel, or non-ferrous metals, this machine ensures a high level of precision and surface integrity.

Key Features and Advantages of the Seamless Tube Peeling Machine:

-

Wide Material Compatibility:

The Seamless Tube Peeling Machine can process a wide range of materials, including:-

Ferrous metals: Steel, stainless steel, tool steel, bearing steel, and spring steel.

-

Non-ferrous metals: Copper and its alloys, aluminum and aluminum alloys, titanium and titanium alloys, and magnesium alloys.

This versatility makes the machine suitable for a variety of industries, including manufacturing, construction, automotive, aerospace, and more.

-

-

Precise Surface Treatment:

One of the primary functions of the Peeling Machine is to remove defects such as the decarburization layer (a layer of reduced carbon content on the material’s surface) and cracks that can occur during the initial stages of manufacturing. The machine’s advanced cutting mechanism ensures that the surface of the material is cleaned to a high standard, making it more suitable for further processing such as welding, coating, or machining. -

High Precision and Efficiency:

The Seamless Tube Peeling Machine achieves high precision during both the rough and finish cutting stages. This precision ensures that the material meets stringent dimensional and surface finish requirements. The machine’s ability to remove substantial processing allowances in a single pass allows for high throughput and efficiency, reducing manufacturing time and improving overall productivity. -

Long-Processing Bar Capability:

This machine is particularly well-suited for processing ultra-long bars, shafts, and tubes with large processing allowances. Its robust design can handle materials of varying lengths and diameters, making it an ideal solution for industries that require high-volume production and consistent surface quality. -

Improved Surface Finish:

By removing surface defects and irregularities, the Peeling Machine ensures that the material reaches a higher level of surface finish. This is particularly important for industries such as aerospace and automotive, where surface integrity and smoothness are critical for product performance and durability. -

Efficient Metal Removal:

The peeling process utilizes high-precision cutting tools that remove the surface layer of the material in a controlled manner. This not only enhances the surface finish but also improves the material’s mechanical properties by removing any weak or damaged surface layers. -

Easy to Operate and Maintain:

The Seamless Tube Peeling Machine is designed with user-friendliness in mind. Its intuitive controls make it easy for operators to adjust settings such as cutting depth, speed, and feed rate, allowing for precise customization according to the material and processing requirements. Furthermore, the machine’s robust design minimizes maintenance requirements, ensuring reliable operation over long periods of time.

Applications of the Seamless Tube Peeling Machine:

The Seamless Tube Peeling Machine is used in various industries where precise surface treatment of metal bars, rods, and tubes is required. Key applications include:

-

Steel Industry: The machine is used for processing steel bars, including structural steel, alloy steel, and stainless steel, to remove defects and achieve a smooth, defect-free surface suitable for further processing or use in critical applications.

-

Aerospace: In the aerospace industry, the peeling machine ensures that metal shafts and tubes used in aircraft components are free from surface irregularities and have the required precision.

-

Automotive: The machine is used to process materials used in automotive components, where surface finish and dimensional accuracy are critical for performance and safety.

-

Manufacturing: In general manufacturing, the Peeling Machine is used to process bars and tubes for use in a variety of applications, including machinery, equipment, and structural components.

-

Precision Engineering: For industries that require high-precision parts, such as the production of bearings, gears, and shafts, the Seamless Tube Peeling Machine ensures that the material meets the required standards for smoothness and dimensional accuracy.

Production Process:

The Seamless Tube Peeling Machine undergoes a multi-step manufacturing process to ensure the highest quality and performance. These steps include:

-

Forging: The material is forged into the desired shape and size.

-

Rough Machining: The material is processed to remove large amounts of material and prepare the surface for finishing.

-

Heat Treatment: The material is heat-treated to enhance its mechanical properties, such as hardness and toughness.

-

Finishing: Fine machining is performed to achieve the final surface finish and dimensions.

-

Packaging: The finished product is carefully packed to prevent damage during shipping.

Quality Assurance:

Our Seamless Tube Peeling Machines undergo rigorous quality control to ensure that they meet international standards. Each machine is tested for precision, durability, and performance. We also provide detailed MT (Magnetic Particle Test) reports and size reports to ensure that our products meet the required specifications.

Packing and Delivery:

-

Packing Details:

-

The machines are packed in standard wooden cases to prevent damage during transport.

-

The packed machines are then loaded into suitable containers, ensuring safe and efficient delivery.

-

-

Delivery Time:

-

Delivery is typically completed within 30 days after the order is placed, depending on the customer’s location and the specific machine specifications.

-

The Seamless Tube Peeling Machine is an essential tool for industries that require high-precision processing of metal bars, tubes, and shafts. With its ability to remove surface defects, achieve high surface quality, and maintain dimensional accuracy, this machine offers significant benefits in terms of efficiency, cost savings, and productivity. Whether you’re working with ferrous or non-ferrous metals, the Peeling Machine ensures that your materials meet the highest standards of quality, making it an indispensable part of your seemless tube production line and other steels.