Rolling Mill Straightening Rolls

– Precision Tools for High-Quality Straightening

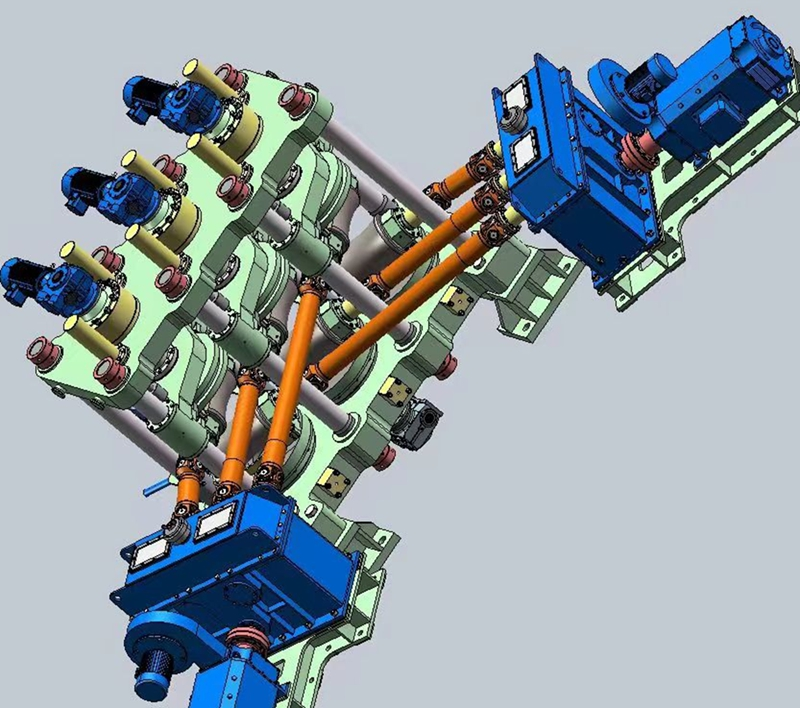

Rolling Mill Straightening Rolls are integral components used in a variety of rolling mills, particularly for straightening pipes, tubes, bars, and other metal products. These rolls are designed to correct the shape and curvature of the metal workpieces, ensuring that they meet the strict dimensional tolerances and surface quality required in various industries. Straightening rolls play a vital role in industries such as seamless tube production, bar rolling, and wire rolling, where precision and high-quality output are essential.

Our Straightening Rolls are manufactured from high-quality materials, with advanced forging, heat treatment, and machining processes that ensure they possess exceptional hardness, wear resistance, and durability. These rolls are designed to maintain peak performance under the toughest conditions, providing a reliable solution for achieving straightness, reducing ovality, and improving the surface finish of metal products.

Straightening roll Specification:

| Name | Straightening roll |

| Application | bar & wire rod mill, hot strip mill, cold strip mill, PC mill, section mill, plate rolling mill and nonferrous mill etc. |

| Process | Forging/Casting – Normalizing & Tempering – Proof Machining- Quenching & Tempering -Subzero treatment — Finish Machining |

| QA/QC | Chemical Composition Report |

| Mechanical Properties Report | |

| UT Report | |

| Heat Treatment Report | |

| Dimensions Check Report | |

| Material Certificates | |

| Standard | ANSI,ASTM,ASME,DIN,GB etc. |

| Certificates | ISO9001; Material Certificates, SGS Certificate. |

Applications of Rolling Mill Straightening Rolls:

Rolling Mill Straightening Rolls are primarily in the following industries:

-

Seamless Tube Mills: These rolls are essential for straightening seamless pipes that have been previously formed, ensuring uniformity and perfect straightness for the pipes.

-

Section Mills: In section mills, straightening rolls are to process various types of metal sections, such as I-beams, channels, and angles, which need to be straightened after rolling.

-

Bar Rolling Mills: Straightening rolls are in bar rolling mills to ensure that steel bars, whether small or large, are accurately shaped and meet industry standards.

-

Wire Rolling Mills: Wire mills utilize straightening rolls to ensure that wire products are free from bends, kinks, and irregularities that could compromise their quality and performance.

-

Cold and Hot Mill Applications: Straightening rolls are for both cold and hot rolling processes to remove any deformation caused by the rolling process and to give the product a smooth and consistent shape.

These rolls are suitable for a wide range of applications, including hot straightening, cold straightening, and high-chromium alloy straightening. They are particularly important in processes where the metal products require precise straightness and dimensional accuracy.

Features and Advantages of Rolling Mill Straightening Rolls:

-

High-Quality Forged Steel Construction:

Our straightening rolls are from high-quality forged steel, which ensures excellent hardness, toughness, and resistance to wear. The forging process enhances the mechanical properties of the rolls, making them capable of withstanding the high forces and temperatures encountered during straightening. -

Exceptional Wear Resistance:

The steel used in the manufacturing of these straightening rolls is specially for its wear resistance. This ensures a long service life even under heavy-duty conditions. Whether used in hot or cold rolling, the rolls maintain their shape and function, reducing the need for frequent replacements and lowering maintenance costs. -

Customizable Designs:

We offer custom-made straightening rolls designed to meet specific customer requirements. Over the years, we have designed rolls in various shapes and sizes to accommodate different types of metal products, from small bars to large pipes and tubes. Our team works closely with clients to ensure the rolls meet their exact specifications and operational needs. -

High Precision:

Straightening rolls play a critical role in achieving the desired straightness and dimensional accuracy of metal products. By carefully controlling the amount of pressure applied during the straightening process, our rolls help eliminate defects such as ovality, curvature, and surface irregularities. -

Enhanced Performance:

With our straightening rolls, metal manufacturers can expect consistent and reliable performance. The rolls ensure that metal products pass through the straightening process with minimal deformation, resulting in higher-quality finished products that meet industry standards. -

Versatile Use:

Our straightening rolls are suitable for various processes, including hot straightening, cold straightening, and alloy steel processing. Whether you are working with seamless tubes, bars, sections, or wires, our rolls provide effective solutions for a wide range of metalworking needs.

Production Process of Rolling Mill Straightening Rolls:

-

Forging: The first step in the manufacturing process involves forging high-quality steel billets to create the initial shape of the rolls. This step is essential for achieving the desired mechanical properties and ensuring durability.

-

Rough Machining: After forging, the rolls undergo rough machining to achieve a basic shape that is suitable for the next steps in the manufacturing process. This process involves removing excess material and shaping the roll to the required dimensions.

-

Heat Treatment: The rolls undergo heat treatment to improve their hardness and wear resistance. This step ensures that the rolls can withstand the high pressures and temperatures encountered during the straightening process.

-

Finishing: Once heat-treated, the rolls undergo finishing machining to achieve precise dimensions and a smooth surface finish. This step is critical for ensuring the rolls operate smoothly and efficiently in the straightening process.

-

Packaging: After completing the machining process, the straightening rolls are in standard wooden cases and loaded into suitable containers for shipment. The packaging ensures that the rolls are protected from damage during transit.

Quality Assurance:

At TED, we take quality seriously. Our straightening rolls undergo rigorous quality control to ensure they meet the highest standards. Our quality assurance process includes:

-

Magnetic Particle Testing (MT): This test is conducted to detect any internal defects or cracks in the rolls.

-

Size Reports: Detailed size reports are provided to ensure that the rolls meet the exact specifications required for the customer’s production line.

-

Wear Resistance Testing: We test the wear resistance of our straightening rolls to ensure they provide optimal performance throughout their service life.

Packing and Delivery:

-

Packing Details:

-

Wooden Case Packaging: Our straightening rolls are securely in standard wooden cases to prevent any damage during transit.

-

Proper Container Loading: Our workers carefully load the rollers into containers to ensure safe transportation.

-

-

Delivery Time:

-

The standard delivery time is approximately 30 days after payment, ensuring timely delivery to meet your production needs.

-

Applications in Various Industries:

The Rolling Mill Straightening Rolls are widely in industries that require high-precision metal products, including:

-

Metalworking and Steel Industry: Essential for shaping and straightening bars, rods, tubes, and wires to the required specifications.

-

Automotive Manufacturing: Used to straighten bars and tubes for use in automotive components.

-

Construction: Ensures that metal reinforcement bars and pipes straightened to precise specifications.

-

Aerospace: In aerospace manufacturing, straightening rolls ensure that tubes and rods used in aircraft components meet strict straightness and quality standards.

Rolling Mill Straightening Rolls are essential tools for achieving high-quality straightness and dimensional accuracy in various metalworking applications. Made from high-quality forged steel and designed for high performance, these rolls offer excellent wear resistance and long service life. Whether used in seamless tube mills, bar rolling mills, or wire rolling mills, they ensure that metal products are perfectly straight and meet the stringent standards required in industries such as aerospace, automotive, and construction.