Straightening Mill and Parts

– High Precision Straightening for Seamless Metal Tubes and Rods

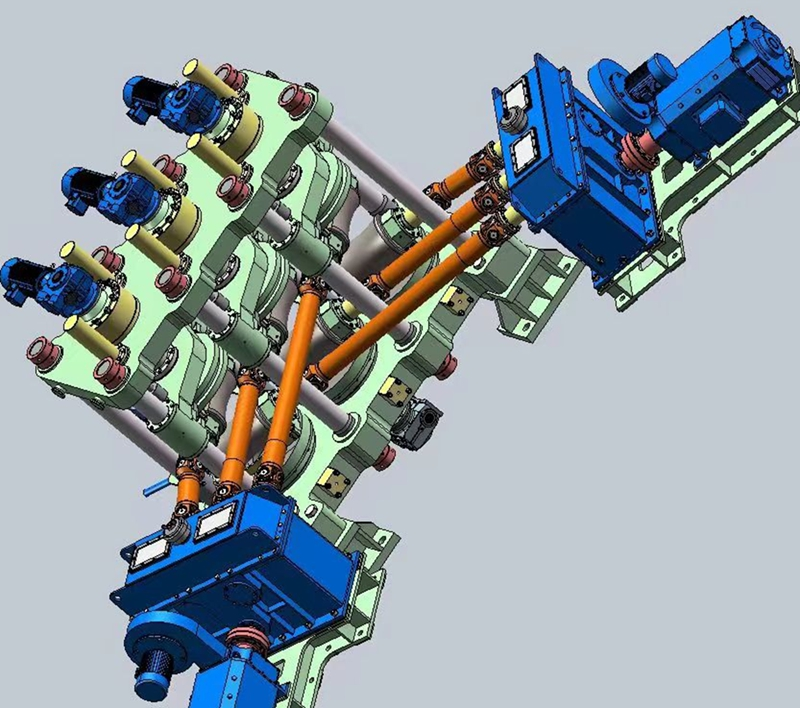

The Straightening Mill and Parts are essential pieces of equipment in the metalworking industry, particularly for the production and finishing of seamless pipes and rods. These machines are designed to correct the camber, reduce ovality, and improve the surface smoothness of metal workpieces such as round tubes and rods. The horizontal straightening machine, commonly used in various manufacturing processes, straightens metal tubes or rods by passing them through a set of rollers that gradually align the workpiece. The machine’s design, with its elliptical curve die rollers, ensures that metal pieces are processed efficiently and accurately.

Functionality of the Straightening Mill:

The primary function of the Straightening Mill is to correct the shape of metal tubes or rods that have deviated from their ideal straight form. Whether due to bending during previous stages of the manufacturing process or inherent material properties, straightening ensures that the workpieces meet the required dimensional and geometric specifications for downstream processes or final applications.

The process involves inserting one end of the round tube or rod into the gap between two sets of rollers. The machine’s motor, combined with a multi-speed reducer and a chain-driven bilateral transmission, pushes the rollers forward. These rollers apply controlled pressure on the workpiece, straightening it as it moves through the machine. The rollers are strategically positioned in an inclined arrangement to apply consistent pressure and force, gradually eliminating the camber, ovality, and curvature from the tube or rod.

Key Features of the Straightening Mill:

-

Horizontal Roller Design:

The machine features horizontal rollers arranged in a cross configuration. The rollers are designed with an elliptical curve die, which ensures that the workpieces are straightened uniformly. This design ensures that metal pieces are gently guided and manipulated to achieve the desired level of straightness. -

Concave and Convex Rollers:

The concave and convex rollers are one of the most distinctive features of the Straightening Mill. The workpiece passes through the gap between these rollers, which apply the required bending force. The convex rollers bend the material, while the concave rollers work in tandem to help straighten the material without overstretching it. -

Continuous Full-Circumference Straightening:

As the workpiece passes through the rollers, it rotates and advances continuously, ensuring that full circumferential straightening is applied. This process improves the straightness of the workpiece uniformly across its length, ensuring consistent results with minimal defects. -

High Yield Strength and Surface Finish:

The straightening machine is particularly effective in straightening high yield strength and small bending metal bars. This is crucial in industries that require precise metalworking, such as aerospace, automotive, construction, and oil and gas. The straightened workpieces also exhibit improved surface roughness, making them suitable for subsequent processing steps like coating, welding, or other finishing techniques. -

Adjustable Deflection Control:

The straightening mill operates through a series of top and bottom rollers. The deflection required to straighten a bar or rod is determined by the convex bottom work roll, which bends the metal over the concave top work roll. The angle at which the top work roll is set determines the maximum amount of deflection that can be applied to the workpiece, providing precision and flexibility to meet specific requirements. -

Efficient Straightening Process:

The machine’s design ensures that the straightening process is both efficient and precise. With high-speed operation and low maintenance, the Straightening Mill enhances overall productivity by reducing the need for manual intervention and increasing throughput in high-demand environments.

Applications of the Straightening Mill:

The Straightening Mill is widely used in industries that require metal bars and rods to be straightened before they undergo further processing or are used in final applications. Some key industries that benefit from this equipment include:

-

Steel Industry: Used to straighten alloy steel bars and rods, ensuring they meet precise dimensional standards before they are used in structural applications.

-

Aerospace: For straightening high-strength metal bars and rods used in the manufacturing of aircraft components, ensuring both straightness and surface quality.

-

Automotive: In the production of components such as exhaust pipes, chassis, and other structural parts, where dimensional accuracy and straightness are critical.

-

Oil & Gas: Straightening pipes and rods used in drilling and transportation, ensuring they meet the required specifications for fluid and gas transfer.

-

Construction: For producing metal reinforcement bars and other structural components that require straightening before installation.

Parts and Components of the Straightening Mill:

The Straightening Mill is composed of several key parts that ensure the proper functioning of the machine and its ability to produce high-quality straightened metal products:

-

Straightening Rollers: These rollers are the primary tools responsible for straightening the workpiece. Made from durable materials, they can withstand the high pressures and forces applied during the straightening process.

-

Roller Boxes: These enclosures house the rollers and ensure that they are correctly positioned and aligned for maximum efficiency during the straightening operation.

-

Motor and Drive System: The motor powers the entire straightening process, with a multi-speed reducer belt pulley system that controls the movement of the rollers. The drive system also includes bilateral chain transmissions to maintain synchronization and precision.

-

Adjustment Mechanisms: These components allow for precise adjustment of the roller gap and the angle of the top and bottom rollers. This ensures that the correct amount of deflection is applied to the workpiece, enabling effective straightening.

-

Control System: A sophisticated control system allows operators to monitor and adjust the machine’s operation, ensuring consistent results across different batches of workpieces. This system also provides feedback on the straightening process, enabling fine-tuning for optimal performance.

Advantages of Using the Straightening Mill:

-

Improved Straightness: The primary advantage of using the Straightening Mill is the significant improvement in the straightness of the metal tubes or rods. This is crucial for applications that require high-precision parts, such as in aerospace or automotive manufacturing.

-

Reduced Ovality: The straightening process reduces the cross-section ovality of the workpiece, ensuring that the final product has a uniform, round shape, which is essential for further processing or use in critical applications.

-

Enhanced Surface Quality: The smoothness of the workpiece’s surface is greatly improved, eliminating any surface defects like burrs or irregularities left by previous processes.

-

High Efficiency: The machine operates at a high speed, allowing for quick processing and reduced downtime. This leads to increased productivity in high-volume manufacturing environments.

-

Cost-Effective: By improving straightness and surface quality, the straightening mill reduces the need for additional finishing steps, saving time and costs associated with post-straightening treatments.

The Straightening Mill and Parts is an indispensable tool in metalworking, particularly in the production of seamless tubes and rods. With its precision roller design, adjustable deflection control, and ability to improve the straightness, ovality, and surface quality of metal workpieces, it ensures that the final product meets the highest standards. Whether used in the steel, aerospace, automotive, or construction industries, the Straightening Mill plays a crucial role in achieving high-quality, dimensionally accurate metal products.