Piercing Mill Roller

Piercing Mill Roller is the main tool of rolling deformation, which plays an important role in ensuring the quality of steel tube production.

Forged Piercer roller material:

Ⅰ. 65Mn

chemical composition of 65 Mn:

| C | Si | Mn | S | P | Cr | Ni | Cu |

| 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 |

Hardness: 260-280HB

Ⅱ.C55

chemical composition of C55:

| C | Si | Mn | S | P | Cr | Ni | Cu |

| 0.52-0.60 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.30 | ≤0.25 |

Piercer rolls must exhibit a high resistance to wear and good gripping ability under alternating mechanical and thermal stresses.After the surface treatment,the piercer rolls have high friction,and it can provide good conditions for pipe milling.

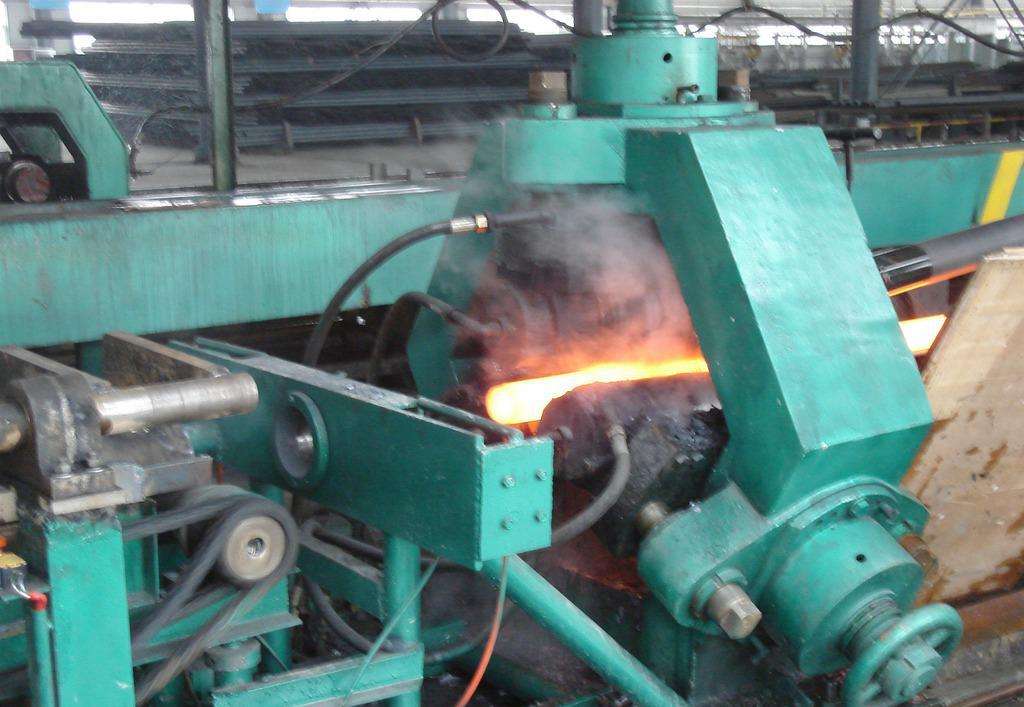

Please the blow pictures for the processing of piercer rolls.

Production process :

- Forged material

- Quenching and tempering

- Finish machining

- Assembly

- packing

Quality Assurance :

MT report ,UT report and Size report will be supplied before shipment

Hot Tags: roll for piercing mill, China, manufacturers, suppliers, factory, plant, customized, piercing mill roller, piercing mill plug, piercing plug head, two roller cross rolling piercer, piercing guide shoes, piercing plug