Steel Rebar Rolling Mill Machine | High-Speed Deformed Bar Production

Precision Rebar Rolling Mill Solutions

KWM Machinery’s Steel Rebar Rolling Mill Machine delivers 150-200 TPH output of ASTM A615, GB/T 1499.2, and BS 4449 compliant deformed bars, achieving ±0.5mm diameter tolerance and 600MPa yield strength. Our systems integrate thermo-mechanical controlled processing (TMCP) for superior ductility, reducing rolling energy consumption by 25% versus conventional mills.

Steel Rebar Rolling Mill Machine Key Features

-

High-Efficiency Rolling

-

Product Range: Φ8mm-Φ40mm deformed bars

-

Rolling Speed: 18-35m/s (adjustable via AI optimization)

-

Temperature Control: 950-1100°C precision in finishing stands

-

-

Smart Process Integration

-

Automatic rib pattern adjustment (3D profiling rolls)

-

IoT-enabled predictive maintenance for roll assemblies

-

-

Energy Recovery

-

Regenerative DC drives recover 15% braking energy

-

Waste heat utilization for preheating billets

-

| Rolling Mill Type | High-Speed TMT Rebar Rolling Mill Production Line |

| Input Material | 150x150x12000mm Steel Billet |

| Steel Grade | High/Low Alloy Steel, Structure Steel, Carbon Steel |

| Rolling Speed | 12-18 meters/second |

| Finished Product Size | Rebar: Φ8 mm, Φ 10 mm, Φ 12mm,Φ14 mm, Φ16mm, Φ 20 mm,Φ24mm,Φ32 mm Length: 12000mm |

| Annual Capacity | 600,000 Ton/Year |

High-Speed TMT Rebar Rolling Mill Production Line

-

General Overview

-

Annual Capacity: 600,000 tons

-

Process Type: Fully automatic continuous rolling

-

-

Billet Specifications

-

Billet Dimensions: 150×150×12,000 mm

-

-

Product Specifications

-

Rebar Diameter Range: Ø8–Ø32 mm

-

Standard Length: 12,000 mm

-

-

Mill Stand Configuration

-

Roughing Mill Section

-

Mill Type: Short-stressed rolling mill

-

Roll Diameter: Ø550 mm

-

Number of Stands: 6

-

Arrangement: Horizontal/vertical alternating

-

-

Intermediate Mill Section

-

Mill Type: Short-stressed rolling mill

-

Roll Diameter: Ø420 mm

-

Number of Stands: 6

-

Arrangement: Horizontal/vertical alternating

-

-

Finishing Mill Section

-

Mill Type: Short-stressed rolling mill

-

Roll Diameter: Ø320 mm

-

Number of Stands: 6

-

Arrangement: Horizontal/vertical alternating

-

Special Feature: 3 stands with horizontal/vertical interchangeable design

-

-

-

Key Performance Parameters

-

Rolling Speed: 12–18 m/s

-

| Specification and Technical Parameter | ||||

| Capacity(T/Hour) | Working hours(Year) | Electricity consumption | Feeding section | Rolling Specification |

| 5 | 2400 | 5MW | 60*60mm | Φ6.5-32mm |

| 8 | 2400 | 8.5MW | 70*70mm | Φ6.5-32mm |

| 10 | 3600 | 9.5MW | 90*90mm | Φ6.5-32mm |

| 15 | 3600 | 10MW | 120*120mm | Φ6.5-32mm |

| 20 | 6000 | 15MW | 120*120mm | Φ6.5-32mm |

| 35 | 6000 | 26MW | 150*150mm | Φ6.5-32mm |

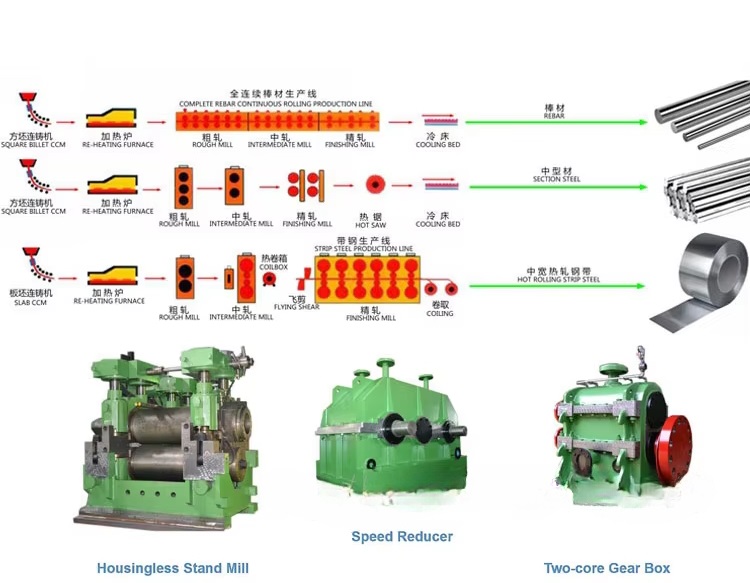

Steel Rebar Rolling Mill production line Components

Mill stand

Roller

Roller bearing

Rack

Rail support

Roll adjusting device

Upper roll balancing device

Transmission device

Auxilliary equipment

Rolling Mill Process

Heating furnace——come out furnace/CCM——Rough Roll——Intermediate Roll——

Pre-finish Roll——-Finished Product——-Packing

Steel Rebar Rolling Mill Machine Technical Advantages

-

Quality Consistency:

∙ Rib height variation ≤0.15mm (EN 10080)

∙ Surface defect detection via laser scanners -

Material Flexibility:

∙ Low-carbon steel (HRB400) | Seismic-grade (HRB500E) -

Emission Control:

∙ Dust emissions ≤10mg/Nm³ (GB 28665)

Steel Rebar Rolling Mill Machine Applications

| Industry | Rebar Grades | Standards |

|---|---|---|

| High-Rise Construction | HRB500E seismic bars | GB/T 28900 |

| Infrastructure | ASTM A706 weldable rebar | AWS D1.4 |

| Precast Concrete | BS 4449:2005 Grade B500B | EN 1992-1-1 |

| Earthquake Engineering | JIS G3112 SD390/SD490 | AIJ Standard |

Certifications & Quality

-

CE & ISO 50001 Certified

-

Performance Validation:

∙ 72hr continuous rolling test (yield strength CV ≤3%)

∙ Rib geometry compliance ≥98% (GB/T 28900)

FAQ

Q: What’s the minimum billet size required?

A: 150x150mm continuous cast billets (max 12m length).

Q: Can you produce epoxy-coated rebar?

A: Yes – in-line quenching & self-tempering (QST) compatible.

Q: How to reduce roll wear?

A: Tungsten carbide rolls (HRC 65) extend lifespan to 50,000 tons.