Industrial Steel Pipe Laser Cutting Machine Solutions

High-Precision Tube Processing | KWM Machinery

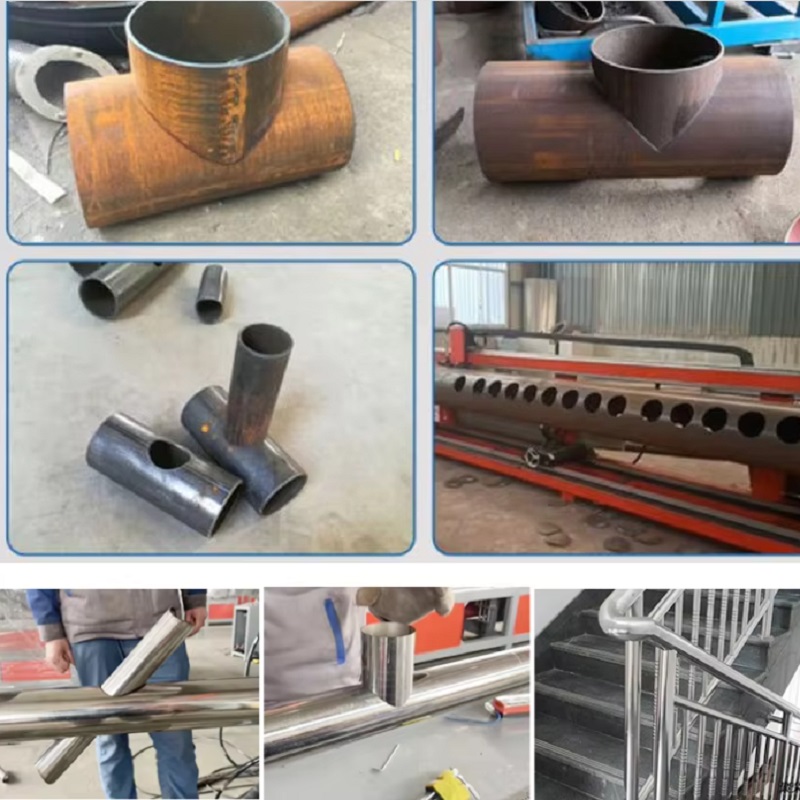

KWM Machinery’s Steel Pipe Laser Cutting Machine delivers micron-level precision for carbon steel, stainless steel, and alloy tubes with ±0.05mm positional accuracy. Designed for API 5L pipelines, ASTM A312 process pipes, and EN 10296 structural hollow sections, our systems achieve 98% material utilization through AI-optimized nesting algorithms.

Steel Pipe Laser Cutting Machine Specification Sheet

| Product name | CNC pipe intersecting line Steel Pipe Laser Cutting Machine | |||

| model | 3P250-KWM | P520-KWM | 3P250-KWM | 3P520-KWM |

| Tube diameter cutting range | 50-260mm | 50-Φ520mm | 50-260mm | 50-520mm |

| Tube length | 3000mm(Adjust according to the actual tube length) | |||

| Custom information | 1 length of equipment can be customized and extended according to length of the user’s pipe. 2 For pipes with a weight of more than 1 ton, a motor of 1.5KW and above is required, and a heavy-duty pipe cutting machine can also be customized. 3 If need bevel cutting function, please choose our five-axis four-linkage pipe cutting machine. 4 If need to cut rectangular tubes, please choose a square tube cutting machine. 5 If need a tube-sheet integrated machine, please contact us. |

|||

| Transmission configuration | 86 series 120 stepping motor + reducer | Panasonic 750W servo motor + reducer | ||

| Number of moving bodies and cutting torches | ,Single movable body, can be equipped with a plasma and a flame cutting torch to switch between use | |||

| Torch height adjustment type | Plasma arc voltage automatic increase or flame capacitance automatic increase | |||

| Number of axes | Three axis two linkage | |||

| Input voltage and power | Single AC 220V 800W | single AC 220V 1200W | ||

| Running accuracy | ±0.2mm/m | |||

| Flame cutting thickness | Perforation capacity: 5-60mm Edge cutting: 5-120mm, | |||

| Plasma cutting thickness | LGK120mm(1-20mm) LGK160mm(1-25m) LGK200m(1-3mm) LGK300m(1-35mm) Depends on the cutting ability of the plasma power supply |

|||

| System, software and height controller | 10.4 inch color screen multi-language display system, 2-axis standard version nesting software, ZZ-PTHC height adjustment, remote control, |

|||

| Maximum pipe weight | <500kg | <1000kg | ||

| Required installation space | L3.7mxW1mxH1.7m | L4mxW1mxH2m, | ||

| Package size | 3970x1160x1690mm | |||

Steel Pipe Laser Cutting Machine Key Features

-

Advanced Laser Technology

-

Fiber Laser Source: 3kW-20kW IPG/TRUMPF modules

-

Cutting Capacity:

∙ Diameter: Φ10mm-Φ600mm

∙ Wall Thickness: 0.5-25mm (carbon steel) -

Beam Quality: M² ≤1.2 for clean kerfs

-

-

Smart Automation

-

6-axis robotic manipulator (±0.01° repeatability)

-

Automatic tube loading/unloading (3-12m lengths)

-

-

Energy Efficiency

-

30% lower power consumption vs. CO₂ lasers

-

Active cooling system (25°C ±0.5°C)

-

Steel Pipe Laser Cutting Machine Technical Advantages

-

Cutting Precision:

∙ Ovality compensation ≤0.1mm

∙ Burr-free edges (Ra ≤3.2μm, EN ISO 9013) -

Material Flexibility:

∙ Carbon steel | Duplex SS (2205) | Aluminum (6061-T6) -

Quality Control:

∙ Real-time vision inspection (0.02mm/pixel resolution)

∙ Automatic bevel cutting (0-45° angles)

Applications

| Industry | Typical Products | Standards |

|---|---|---|

| Oil & Gas | API 5CT casing connectors | ASME B16.25 |

| Automotive | Exhaust system components | ISO 9013 |

| Construction | EN 10219 structural nodes | AWS D1.1 |

| Medical | 316L SS implant fixtures | ASTM F138 |

Certifications & Compliance

-

CE & ISO 13485 Certified (medical-grade systems)

-

Safety Standards:

∙ Laser Class 1 enclosure (EN 60825-1)

∙ Fume extraction efficiency 99.95% (OSHA 1910.1000)

FAQ

Q: What’s the minimum bend radius for cutting?

A: 1.5x pipe diameter with our adaptive 3D head.

Q: Can you process coated pipes?

A: Yes – galvanized/painted surfaces protected via gas shielding.

Q: How to ensure cutting head alignment?

A: Auto-calibration with laser interferometry every 8 hours.

Unlock Next-Gen Tube Fabrication Capabilities

✅ Request Free Sample Cutting – Test your materials with our 20kW demo machine.

✅ Download Cutting Parameter Guide – Optimize speeds/feeds for 50+ alloys.

✅ Book Live Webinar – Watch real-time cutting of API 5L X70 pipes.

We also have Steel tube Rolling mill for whole production line –hot rolling mill and cold rolling mill.please contact for more details.